Navigeren door Disruptie: AI en Analyse voor Flexibiliteit en Responsiviteit van de Supply Chain

The Evolving Landscape of Supply Chain Disruption

Supply Chain Resilience in a Changing World

The global supply chain is no longer a static network; it's a dynamic, ever-evolving system responding to geopolitical shifts, economic fluctuations, and unexpected disruptions. Understanding and adapting to these changes is crucial for businesses to maintain operational efficiency and profitability. Supply chain resilience, the ability to withstand and recover from disruptions, has become a critical component in ensuring business continuity.

Companies are increasingly recognizing the importance of diversifying their supply sources and building redundancy into their operations. This proactive approach allows them to mitigate risks associated with single points of failure and maintain a steady flow of goods and services, even during periods of uncertainty.

Technological Advancements and Supply Chain Optimization

Technological advancements are revolutionizing the way supply chains operate. From sophisticated logistics platforms to real-time tracking systems, technology is enabling businesses to optimize their processes and gain greater visibility into their operations. This improved visibility leads to more efficient inventory management and reduced lead times.

The integration of artificial intelligence (AI) and machine learning (ML) is further enhancing supply chain optimization. These technologies allow for predictive analysis, enabling businesses to anticipate potential disruptions and proactively adjust their strategies to mitigate risks.

The Impact of Geopolitical Instability on Supply Chains

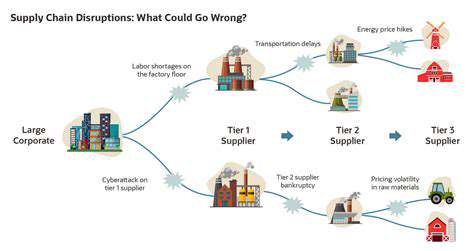

Geopolitical instability, including trade wars, political tensions, and natural disasters, can severely disrupt supply chains. The reliance on specific regions or countries for critical components can leave businesses vulnerable to unforeseen events, creating significant challenges in maintaining production schedules and meeting customer demands.

Companies are forced to reassess their supply chain strategies, exploring alternative sourcing options and diversifying their supplier networks to reduce their dependence on single regions. This adaptation is crucial for ensuring long-term resilience and stability in the face of global uncertainties.

Ethical Considerations and Sustainability in Supply Chains

Ethical considerations and sustainability are becoming increasingly important factors in supply chain management. Consumers are demanding greater transparency and accountability from companies regarding the ethical treatment of workers and the environmental impact of their operations. Companies are recognizing that integrating sustainability into their supply chains can enhance brand reputation, attract socially conscious customers, and potentially lower operational costs in the long run.

Implementing sustainable practices, such as reducing carbon emissions and promoting fair labor standards, is not merely a trend, but a crucial aspect of building a resilient and responsible supply chain for the future.

The Future of Supply Chain Management

The future of supply chain management hinges on the ability to adapt to rapidly changing circumstances. This means developing more agile and flexible strategies that can respond quickly to disruptions. Embracing new technologies, fostering collaboration among stakeholders, and prioritizing ethical considerations will be key elements in shaping the future of supply chains.

Companies will need to embrace a more holistic view of their supply chains, considering not just the efficiency and cost-effectiveness, but also the social and environmental impact of their operations. This approach will ultimately contribute to building more resilient and sustainable supply chains that can thrive in the decades to come.

Optimizing Inventory Management with Analytics

Understanding Inventory Management Fundamentals

Effective inventory management is crucial for any business aiming to maximize profitability and minimize waste. It involves a complex interplay of factors, from forecasting demand to controlling storage space. A well-structured inventory management system should provide real-time visibility into stock levels, enabling proactive adjustments to meet fluctuating customer needs. Understanding the nuances of inventory turnover, carrying costs, and storage space optimization is critical to long-term success.

The core principles of inventory management, such as the FIFO (First-In, First-Out) method, are vital for maintaining product quality and reducing spoilage. Implementing these principles helps to ensure that older stock is used first, preventing obsolescence and maximizing the lifespan of products. This proactive approach is key to minimizing losses and ensuring smooth operations.

Forecasting Demand and Supply

Accurate forecasting is the cornerstone of effective inventory management. Businesses must anticipate future demand to prevent stockouts or excess inventory. This involves analyzing historical sales data, considering market trends, and identifying potential disruptions to supply chains. By accurately predicting demand, businesses can optimize their procurement strategies and avoid costly mistakes.

Supply chain disruptions can significantly impact inventory levels. Understanding potential disruptions, such as natural disasters, geopolitical events, or unexpected supplier issues, is essential for proactive risk management. Developing contingency plans for these unforeseen circumstances is critical to maintaining smooth operations and minimizing the impact on production and sales.

Optimizing Storage and Handling

Efficient storage and handling practices are essential for minimizing inventory costs and maximizing space utilization. Implementing well-organized storage systems, such as using racking and shelving, can significantly improve the efficiency of picking, packing, and shipping orders. This not only optimizes space utilization but also reduces the time required for order fulfillment.

Careful consideration of warehouse layout and material handling equipment can significantly impact inventory management. Strategic placement of items and the appropriate use of forklifts, conveyor belts, or automated systems can reduce the time and labor costs associated with moving and storing inventory. This in turn, directly contributes to overall operational efficiency.

Implementing Inventory Control Systems

Utilizing inventory control systems, such as barcode scanners or automated inventory tracking software, is critical for maintaining accurate records. These systems provide real-time updates on stock levels, enabling businesses to identify potential issues proactively. This data-driven approach facilitates better decision-making regarding procurement, storage, and distribution.

Implementing a robust inventory control system allows for detailed tracking of inventory movements. This detailed history facilitates accurate reporting and analysis, providing valuable insights into trends and areas for improvement. This helps in identifying potential bottlenecks and streamlining the entire inventory process.

Inventory Valuation and Cost Accounting

Accurate valuation of inventory is critical for financial reporting and decision-making. Choosing the appropriate valuation method, such as FIFO, LIFO, or weighted-average cost, impacts the reported cost of goods sold (COGS). Businesses must carefully consider the implications of different valuation methods on their financial statements and profitability. Proper inventory valuation procedures are essential for maintaining accurate financial records.

Effective cost accounting practices are integral to inventory management. Careful tracking and analysis of inventory costs, including storage, handling, and obsolescence, are necessary for accurate cost estimations and pricing strategies. A sound understanding of these costs is crucial for making informed decisions about inventory levels and pricing adjustments.

Building a Resilient Supply Chain for the Future

Optimizing for Unpredictability

Building a resilient supply chain isn't about predicting the future, it's about preparing for the inevitable disruptions. Modern supply chains are complex webs of interconnected processes, and unexpected events – from natural disasters to geopolitical instability – can easily throw everything out of kilter. A resilient system, however, anticipates these potential disruptions and incorporates flexible strategies to navigate them effectively. This proactive approach requires a deep understanding of potential vulnerabilities and the ability to adapt quickly and efficiently when problems arise.

Proactive risk assessment, including scenario planning and stress testing, is paramount. Understanding the potential impact of various disruptions on different parts of the supply chain allows businesses to develop contingency plans and allocate resources strategically to mitigate risks. This involves identifying potential bottlenecks, weak links, and dependencies within the network.

Leveraging AI-Powered Insights

Artificial intelligence (AI) and advanced analytics are transforming how businesses approach supply chain resilience. AI algorithms can analyze vast amounts of data from various sources, identifying patterns and anomalies that might signal potential disruptions before they escalate. Predictive models can forecast demand fluctuations, assess supplier risks, and even anticipate potential disruptions based on historical trends and real-time market data.

This data-driven approach empowers businesses to make informed decisions, optimize inventory levels, and proactively adjust production schedules to minimize the impact of disruptions. AI-powered systems can also help automate tasks, improve communication across different parts of the supply chain, and accelerate response times in the event of unforeseen circumstances.

Strengthening Supplier Relationships

A resilient supply chain isn't just about internal optimization; it's about fostering strong, reliable relationships with suppliers. Diversifying supplier networks and establishing backup plans for critical suppliers can minimize the impact of a single point of failure. Building trust and transparency with suppliers through open communication and collaboration is essential. This includes sharing information about potential disruptions and working together to find solutions.

This collaborative approach can lead to more flexible and adaptable supply chains, enabling businesses to react quickly to unforeseen events and maintain operational continuity. Stronger relationships also translate into greater responsiveness and agility in the face of disruptions, ensuring a more sustainable and robust supply chain.

Embracing Automation and Digitalization

Automation and digitalization play a crucial role in building a resilient supply chain. Automated systems can streamline processes, improve efficiency, and reduce human error, making the supply chain more adaptable to changing circumstances. Real-time visibility into inventory levels, production status, and transportation movements is essential for rapid response and proactive decision-making. This data transparency and agility are vital in the face of potential disruptions.

Implementing digital platforms and technologies can enhance communication and coordination across the supply chain, allowing for quicker responses to disruptions and more effective collaboration among different stakeholders. This ultimately leads to a more flexible and responsive supply chain, capable of navigating unexpected challenges with greater ease.

Proactive Risk Management Strategies

Proactive risk management is an integral part of building a resilient supply chain for the future. Developing and implementing robust risk assessment frameworks is crucial to identify potential vulnerabilities and develop mitigation strategies. This includes considering geopolitical instability, natural disasters, pandemics, and other disruptions that can affect the supply chain.

Regularly reviewing and updating these risk management strategies is essential. The ever-changing global landscape necessitates adaptability and a willingness to adjust strategies based on emerging trends and new information. This continuous improvement process helps ensure the supply chain remains robust and resilient in the face of future challenges.

- Hoe voorkom je dat je hond aan meubels knaagt

- Hoe om te gaan met vergiftiging bij honden door huishoudelijke artikelen

- Uw hond voorbereiden op een vliegreis

- Hoe je hond te trainen om uit een reisfles te drinken

- De beste koele vesten voor actieve honden

- Veel voorkomende gezondheidsproblemen bij oudere honden en preventietips

- Hoe je hond te helpen om zich aan te passen aan een nieuw baby'tje thuis

- Ver voorbij menselijke grenzen: De toekomst van robotica in de toeleveringsketen

- De strategische betekenis van geavanceerde robotica voor de efficiëntie van de toeleveringsketen

- Versterking van het merkvertrouwen door zichtbaarheid in de toeleveringsketen

- Generatieve AI voor optimalisatie van supply chain routes: slimmer en sneller plannen

- Innovatie omarmen: de sleutel tot supply chain leiderschap