最新文章

-

Small Business, Big Tech: Supply Chain Solutions for SMEs

Leveraging Cloud-Based Solutions for Business FlexibilityIn the rapidly evolving landscape of small and medium-sized enterprises (SMEs), adopting cloud-based solutions is not just an option—it's a necessity. These solutions provide SMEs the flexibility to scale their operations efficiently, enhancing operational effectiveness and delivering substantial cost savings. From storage and data management to specialized applications optimizing supply chain logistics, cloud technology empowers SMEs to adapt to fluctuating market demands with ease. Advantages of Cloud FlexibilityCloud-based solutions offer a myriad of benefits, including scalable resources that adjust to changing business needs. This flexibility is essential for SMEs facing seasonal variations in demand. Furthermore, cloud technology reduces IT management costs, ensures quick deployment of solutions, and minimizes downtime, ultimately boosting productivity. As a result, businesses can respond swiftly to market changes and customer requirements. Essential Features for Supply Chain SolutionsMany cloud supply chain solutions come equipped with real-time tracking, inventory management, and analytics capabilities. These features enable SMEs to gain critical insights into their operations, allowing for informed decision-making that positively influences the bottom line. Enhanced forecasting through cloud-based analytics also helps businesses maintain optimal inventory levels, reducing costs from overstocking or stockouts. How to Choose the Right Cloud ProviderSelecting an appropriate cloud provider is crucial for maximizing the benefits of cloud technology. SMEs should evaluate service reliability, customer support, and security measures. Understanding the pricing model is vital—opting for pay-as-you-go options can help manage cash flow efficiently while eliminating unexpected costs. Best Practices for ImplementationIt’s important for SMEs to adopt a strategic approach to implement cloud solutions. Identifying pain points and involving key stakeholders facilitates smoother transitions and better user adoption. Training employees on the new systems not only boosts their confidence but also enhances productivity over time. Continuous assessment of implementation success against defined metrics allows for ongoing improvements. Future Trends in Cloud Supply Chain ManagementEmerging technologies like AI and machine learning are set to redefine cloud-based supply chain management, offering opportunities for automation, reduced human error, and optimized resource allocation. Additionally, the integration of IoT devices will provide real-time data, enabling quicker decision-making. Keeping abreast of these trends ensures that SMEs remain competitive and can leverage the latest innovations. The Role of Data Analytics in Decision-MakingIn a competitive marketplace, data analytics plays a crucial role in supply chain management for SMEs. It helps identify inefficiencies, optimize inventory, and foresee market fluctuations. Companies embracing sophisticated analytics have noted reductions in logistics costs while enhancing operational efficiency. Adopting user-friendly analytics tools is essential to empower SMEs to leverage data effectively. Embracing Automation for Cost ReductionAutomation streamlines various processes, reducing manual errors and enhancing productivity. While challenges exist in implementation, especially regarding initial costs, cloud-based solutions often provide a cost-effective pathway for SMEs to adopt automation. A culture of continuous learning and employee involvement can significantly improve the adoption of automated systems. E-Commerce Integration and Sustainable PracticesIntegrating robust e-commerce solutions with supply chain management enhances operational efficiency, allowing SMEs to meet increasing online shopping demands. Furthermore, adopting sustainable practices not only leads to cost savings but also builds a positive brand image. Transparency about sustainability initiatives fosters customer loyalty and trust.In summary, leveraging cloud-based solutions, data analytics, automation, and sustainable practices can significantly enhance the operational capabilities of SMEs, positioning them for success in a competitive business environment. -

Building a Responsible and Transparent Supply Chain

//example.com/static/images/5/2026-01/TheImportanceofTransparencyinSupplyChains.jpg)Transparency in supply chains is more crucial than ever, as consumers increasingly demand ethical practices and an understanding of where their products come from. This web page delves into the significance of supply chain transparency, its benefits, challenges, and the best practices organizations can adopt to enhance accountability and trust among stakeholders. Understanding Supply Chain TransparencySupply Chain Transparency (SCT) refers to the accessibility of information regarding supply chain activities, from sourcing to delivery. According to a 2020 McKinsey study, companies providing transparent information cultivate consumer trust and loyalty. Businesses must not only disclose their suppliers but also divulge their sourcing processes, labor practices, and environmental impacts due to a growing market push for ethical consumption. Benefits of a Transparent Supply ChainA transparent supply chain leads to various advantages:- Increased consumer trust and loyalty.- Enhanced risk management.- Improved compliance with regulations.- Better operational efficiency.A study revealed that 94% of consumers prefer brands that are upfront about their sourcing practices, highlighting the strong correlation between transparency and brand loyalty. Challenges in Achieving TransparencyDespite its benefits, achieving transparency presents challenges, including inconsistent data systems and fears of competitive disadvantages. Many organizations struggle to integrate and share data effectively, which can hinder trust among consumers. Striking a balance between openness and confidentiality remains a critical hurdle. Technological Innovations Enhancing TransparencyEmerging technologies such as blockchain and IoT play pivotal roles in enhancing supply chain transparency. Blockchain ensures immutable records of transactions, enabling real-time tracking of product origins, while IoT devices provide data-driven insights throughout the supply chain. According to PwC, around 40% of executives believe blockchain will enhance transparency significantly. Best Practices for Maintaining TransparencyTo foster a transparent supply chain, businesses should:1. Cultivate a culture of openness within their organization.2. Utilize technology for automated, standardized data collection.3. Establish sustainability standards to demonstrate a commitment to responsible practices. The Future of Supply Chain TransparencyAs consumer expectations evolve, the push for transparency will intensify. A recent Deloitte survey showed that nearly 65% of consumers would pay a premium for products from companies that practice transparency and sustainability. Companies must proactively advance their transparency initiatives to meet these expectations and secure a competitive edge. Key Components of a Responsible Supply Chain- Transparency in Sourcing Materials: Ensuring clear procedures for material sourcing, potentially using blockchain for traceability.- Fair Labor Practices: Committing to ethical worker treatment throughout the supply chain.- Environmental Sustainability Initiatives: Prioritizing sustainability measures to minimize ecological impacts.- Vendor Collaboration and Engagement: Building strong partnerships with suppliers to align ethical and operational standards. ConclusionIn conclusion, supply chain transparency is an essential factor for modern businesses aiming to meet consumer expectations regarding ethical sourcing and sustainability. Organizations embracing transparency will not only build trust and loyalty but also enhance their resilience in navigating an ever-changing market landscape. The integration of advanced technologies and commitment to best practices will be key to successfully implementing transparent supply chains in the future. -

Natural language generation for product recall notifications

- Enhanced efficiency in communication- Error-free, consistent messaging- Applications that range from customer service to product alerts The Crucial Role of NLG in Product RecallsDuring product recalls, clear and prompt communication is essential. NLG facilitates rapid generation of notifications, ensuring stakeholders, including consumers and retailers, are informed quickly. For instance, industries utilizing NLG can issue recall alerts up to 30% faster than conventional methods.NLG allows for tailored messaging, catering to different audience segments. This means that technical jargon can be minimized for general consumers while detailed information can be supplied for industry professionals. This level of customization increases understanding and response rates among diverse demographic groups. Importance of Clear CommunicationTransparency is paramount during recalls. Studies indicate that clear messaging significantly reduces consumer anxiety and fosters brand loyalty. Brands that prioritize transparent communication witness up to a 30% increase in positive consumer perceptions.The impact of well-defined instructions cannot be overstated. Research suggests that clear guidelines for product returns or refunds can boost compliance rates by 20%. Moreover, offering instructions in multiple languages enhances accessibility, helping all consumers navigate the recall process effectively. Challenges and ConsiderationsWhile NLG offers various benefits, implementing it presents challenges such as maintaining language accuracy and compliance with legal standards. Organizations must also balance automation with a human touch, as overly robotic notifications may alienate consumers.Data quality is another critical aspect; inaccuracies can lead to ineffective communications. Therefore, investing in robust data governance practices is essential to ensure that messages are timely, accurate, and relevant. Future Trends in NLGAs technology evolves, so does NLG's role in communication strategies. Potential future developments include:- Greater reliance on machine learning to predict recalls proactively- Integration with voice-assisted technology for more efficient consumer engagement- Enhanced predictive capabilities to identify at-risk products before an official recall is necessaryUltimately, embracing NLG allows companies to fulfill regulatory obligations while building consumer trust. By focusing on the quality of NLG-generated communications and integrating feedback loops, organizations can continuously refine their messaging strategies. ConclusionNatural Language Generation is reshaping the landscape of product recall notifications. Its ability to create clear, actionable messages rapidly not only fulfills regulatory requirements but also strengthens consumer relationships. As organizations consider implementing NLG, the focus on effective data management and continuous improvement will be vital for achieving success in communication strategies. -

The Impact of AI on Supply Chain Labor Force Reskilling

The Necessity for Reskilling in an AI-Driven Supply ChainIn today’s rapidly evolving supply chain landscape, the integration of AI technology is reshaping job roles and requirements. As traditional tasks like inventory management and logistics become increasingly automated, supply chain professionals must adapt or risk falling behind. With projections that automation could displace over 85 million jobs by 2025, the necessity for reskilling has never been clearer. Adapting to ChangeThe demand for new skill sets is paramount. Employees now need to focus on data interpretation and critical decision-making based on AI-generated insights. Unfortunately, over 40% of supply chain workers currently lack essential digital capabilities, hindering organizational productivity and efficiency. Addressing these skill gaps through targeted training initiatives is crucial for maintaining a competitive edge. Building a Continuous Learning CultureOrganizations like Amazon and Walmart are proactively investing in robust training programs focused on advanced technological skills, such as machine learning and analytics. Implementing a culture of continuous learning allows workers to evolve alongside technology. Such initiatives can drive a 21% increase in profitability, emphasizing the importance of employee development in the workplace. Promoting CollaborationCollaboration among team members is essential in a tech-driven environment. With a blended workforce that includes both traditional supply chain roles and data specialists, organizations must foster teamwork to effectively leverage AI tools. Encouraging a knowledge-sharing culture reduces resistance to technology adoption and improves operational efficiency. Future-Proofing the WorkforcePreparing the workforce for future challenges is critical. Companies must prioritize reskilling initiatives that address current gaps and anticipate future trends, including fostering soft skills like adaptability and emotional intelligence. Collaborations with educational institutions can offer employees access to innovative practices and keep them ahead of the curve. Identifying Skills GapsTo effectively develop and implement reskilling initiatives, organizations should conduct a skills gap analysis. Strategies such as employee surveys and performance assessments can uncover deficiencies and facilitate targeted training solutions. Leveraging AI and data analytics can further refine this process, allowing firms to identify specific areas where employees need improvement. Tailored Training ProgramsOnce skills gaps are identified, companies should create tailored training programs that mix various learning modalities, such as online courses, simulations, and hands-on workshops. With platforms incorporating virtual reality and AI-driven personalized learning paths, employees are more likely to engage and acquire necessary skills efficiently. Measuring Effectiveness and ROITo ensure training initiatives are effective, organizations must track key metrics related to employee performance and satisfaction post-training. Regular evaluations enable continuous refinement of training programs, ensuring they align with both individual and organizational goals. ConclusionReskilling in an AI-driven supply chain is not just beneficial—it's essential for business survival. Companies that embrace this challenge by investing in their workforce development not only improve employee retention but also position themselves for future success. By fostering a culture of continuous learning and collaboration, organizations can navigate the complexities of the modern supply chain landscape and thrive amidst constant change. -

Building an AI Driven Supply Chain Control Tower

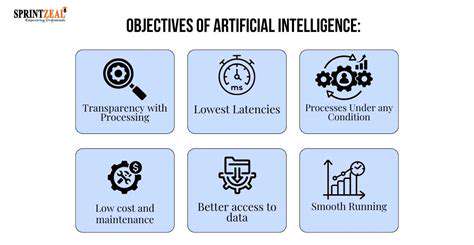

Understanding the Goals of an AI-Driven Control TowerIn today’s fast-paced market, an AI-driven control tower serves as a crucial tool for enhancing supply chain efficiency. Leveraging real-time data, businesses can streamline operations, reduce lead times, and minimize costs. The importance of predictive analytics cannot be understated, as it empowers companies to anticipate demand fluctuations, ensuring optimal inventory levels and resource allocation. Key Benefits of AI-Driven Control TowersWith AI at the helm, organizations gain improved decision-making capabilities. Enhanced data visualization and collaborative platforms foster real-time insights, enabling teams from various sectors to respond swiftly to supply chain challenges. The holistic integration of data from suppliers and logistics partners further bolsters operational visibility, essential for fostering innovation and agility. Predictive AnalyticsResearch indicates that organizations implementing predictive analytics can achieve operational efficiencies exceeding 30%. By identifying patterns and potential disruptions, managers can proactively mitigate risks, ensuring supply chain resilience. This proactive approach not only increases efficiency but also enhances customer satisfaction. Real-Time AnalyticsThe significance of real-time analytics cannot be overstated. These insights allow for timely identification of trends, facilitating quick adaptations within a dynamic marketplace. Companies equipped with advanced AI algorithms and machine learning models can make informed predictions, optimizing routes, managing inventory, and ultimately cutting costs. Future Implications of AI Control TowersAs AI technology continues to evolve, so too will the functionalities of control towers. Emerging technologies, such as blockchain, offer prospects for improved transparency and security among supply chain partners. Companies willing to adapt to these advancements are likely to lead their industries, exemplifying the power of intelligent supply chain ecosystems. Overcoming Challenges in ImplementationDespite the clear advantages of AI-driven control towers, organizations must navigate challenges like data quality, integration, and workforce skills gaps. Ensuring data integrity and efficient integration of systems is paramount. Furthermore, addressing employee resistance to new technologies through transparent change management strategies can facilitate smoother transitions. ConclusionIn conclusion, the successful implementation of AI in supply chain control towers can lead to significant operational benefits. By investing in data governance, training programs, and alignment of initiatives with business goals, companies can harness the full potential of AI technologies. As we move forward, embracing change and fostering a culture of innovation will not only enhance supply chain efficiencies but position organizations for sustained growth and competitive advantage. -

Real Time Data: Transforming Supply Chain Decision Making

Unlocking Efficiency and Decision-Making Understanding Real-Time Data in Supply ChainsReal-time data refers to the immediate availability of critical information as it is generated, transforming the landscape of supply chain management. With instant access to metrics like inventory levels, shipping times, and demand forecasts, businesses can significantly enhance their responsiveness. According to industry research, companies leveraging real-time data can experience a noteworthy 30% reduction in operating costs due to improved visibility and proactive resource management. The Significance of Real-Time DataReal-time data empowers supply chain managers to make timely decisions, facilitating proactive inventory adjustments, immediate responses to disruptions, and enhanced customer service through accurate tracking. By streamlining communication among supply chain partners, organizations can align strategies, leading to more collaborative and effective operations. Investing in real-time analytics systems is thus imperative for businesses aiming to elevate their capabilities. Key Benefits:- Enhanced Visibility: Monitor supplier performance and consumer demand to reduce lead times by 30% and improve logistics.- Improved Decision-Making: Utilize accurate, up-to-date information to prevent overstock or stockouts and align operations with market trends.- Cost Reduction and Increased Efficiency: Optimize delivery routes to significantly cut logistics costs, while minimizing excess inventory reduces warehousing fees. Challenges in ImplementationDespite the advantages, implementing real-time data systems presents challenges. The integration of diverse data sources can be complex, and organizations might face resistance from staff accustomed to traditional systems. Ensuring data accuracy and security is also vital; inaccuracies can undermine the benefits of real-time insights. Businesses must invest in technology, staff training, and robust cybersecurity measures to facilitate a successful transition. Technological Drivers of Real-Time DataThe backbone of real-time data capabilities is anchored in several transformative technologies:- Data Analytics: Powerful tools process large datasets swiftly, enabling companies to make data-driven decisions.- Cloud Computing: Offers scalable solutions ensuring seamless data access across multiple locations.- Internet of Things (IoT): Revolutionizes data collection through sensors and devices, tracking assets in real time.- Artificial Intelligence: Enhances predictive capabilities, allowing for better demand forecasting and inventory management.- Blockchain Technology: Ensures data integrity and transparency, critical for industries requiring authenticity. The Future of Supply Chain ManagementReal-time data analytics are set to become increasingly essential in supply chain decision-making, enabling quicker responses to disruptions and enhancing service levels. The integration of predictive analytics allows companies to forecast demand patterns with increased accuracy, driving significant improvements in operational efficiency. Ultimately, cultivating a data-driven culture within organizations, where strategic decisions are underpinned by real-time insights, is crucial for future growth and competitiveness. As the landscape of supply chain management evolves, businesses that invest in these solutions will be well-positioned to navigate market demands effectively.For a deeper dive into the benefits and challenges of real-time data in your supply chain, contact us today! -

The Importance of Data Ethics in Supply Chain Management

The Future of Data EthicsCompanies that stay ahead of the curve in ethical data practices will secure a competitive edge within their industries. Emerging technologies and a focus on collaboration among stakeholders will drive the development of innovative and responsible data management solutions. By addressing ethical challenges with a forward-looking approach, organizations can ensure ongoing trust from their stakeholders and navigate the complexities inherent in modern supply chains.In summary, embracing data ethics within supply chains is not merely about compliance; it is a strategic imperative that fosters stronger relationships with stakeholders, enhances brand loyalty, and drives business success. For organizations looking to thrive in an increasingly complex data landscape, prioritizing ethical data management is key. -

Machine Learning for Supply Chain Demand Shaping

The Role of Machine Learning in Demand ForecastingMachine learning has become a cornerstone in demand forecasting, revolutionizing the way businesses predict consumer behavior and adjust their strategies. Through advanced algorithms, companies can enhance their predictive accuracy and make informed decisions that ultimately lead to improved profitability. Understanding Machine Learning AlgorithmsMachine learning algorithms, including regression models, decision trees, and neural networks, are pivotal in transforming traditional demand forecasting. By analyzing historical data and identifying patterns, these algorithms enable businesses to predict future demand with high accuracy. It's essential for organizations to select the right algorithm suited to their specific industry needs and operational context, optimizing their forecasts while upholding the integrity of data quality. Importance of Data QualityData quality is crucial when employing machine learning for demand forecasting. Businesses that invest in accurate, timely, and relevant data capture will find their forecasts more reliable and actionable. By integrating internal sales data with external factors like economic indicators and customer sentiment, organizations can create a comprehensive dataset that underpins their predictive efforts. Integrating Machine Learning with Supply Chain OperationsEffective integration of machine learning into supply chain operations is key to achieving agility and responsiveness. Enhanced inventory management, streamlined operations, and significant cost reductions often follow the introduction of machine learning-driven demands forecasts. Notable companies like Walmart and Amazon optimize their inventory distribution using these advanced methodologies, ensuring product availability when and where it's needed. Future Trends in Machine Learning for Demand ForecastingThe future of demand forecasting is bright as machine learning evolves. Innovations such as augmented analytics are set to significantly amplify the predictive capabilities of demand forecasting tools. Furthermore, integrating real-time data from IoT devices will enable companies to adapt swiftly to changing consumer behaviors, ensuring they remain competitive in a rapidly shifting marketplace. Dynamic Pricing Strategies Enhanced by Machine LearningDynamic pricing is essential in industries like e-commerce and travel, allowing businesses to adjust prices based on demand fluctuations. Machine learning amplifies this by analyzing vast datasets to optimize pricing strategies, enabling companies to maximize revenue while also catering to consumer preferences. Factors Influencing Dynamic PricingSeasonality, economic indicators, and competitive pricing can all influence dynamic pricing strategies. Companies must analyze these external conditions alongside consumer sentiment to effectively navigate the pricing landscape. Implementing Machine Learning for PricingFor successful implementation, businesses should gather detailed data and utilize specialized tools designed for dynamic pricing. This approach not only fosters better pricing accuracy but also supports enhanced profitability by leveraging continuous insights driven by machine learning algorithms. Inventory Management Optimization Through Predictive AnalyticsPredictive analytics enables businesses to anticipate consumer demand and optimize stock levels accordingly. Organizations implementing these practices can significantly improve their inventory turnover rates, directly impacting customer satisfaction and profitability. Overcoming Challenges in Predictive AnalyticsImplementing predictive analytics is not without its challenges, including managing siloed data and ensuring data quality. Organizations must focus on developing robust data governance to enable effective forecasting and decision-making. Future of Inventory ManagementLooking ahead, advancements in AI and machine learning will further shape the landscape of inventory management. Enhanced capabilities and intuitive tools are poised to empower even smaller businesses to tap into powerful analytics for sustained competitive advantage.Through the integration of machine learning into demand forecasting, dynamic pricing, and inventory management, businesses can not only enhance their operational efficiencies but also solidify their positions in an increasingly competitive market. -

5G for improved communication in smart warehouses

The ultra-fast capabilities of 5G facilitate real-time updates on inventory levels, reducing operational costs and enhancing resource allocation.- IoT Compatibility: By supporting numerous IoT devices, 5G enhances network resilience and allows for applications like automatic restocking notifications, which streamline warehouse operations. Effective Integration of IoT and 5GThe synergy between IoT devices and 5G networks enables warehouses to monitor stock levels continuously. This integration minimizes human error and empowers managers with actionable insights derived from real-time data analytics. As a result, businesses can make informed decisions more efficiently, boosting supply chain visibility and forecasting accuracy. The Impact on Supply Chain EfficiencyOrganizations leveraging 5G technology report up to a 25% reduction in stockout rates, a crucial metric in today’s fast-paced market. Enhanced speed and visibility empower businesses to quickly adapt to fluctuation in consumer demand, improving delivery timelines and order fulfillment accuracy. Future Trends and Cybersecurity ConsiderationsLooking ahead, advancements in edge computing promise to further enhance data processing capabilities within warehouses. However, as more devices connect to these high-speed networks, ensuring robust cybersecurity measures becomes a critical task to protect sensitive inventory and operational data. Automation and Enhanced Communication5G technology facilitates better coordination between automated systems in smart warehouses. With improved connectivity, robots and IoT devices can communicate instantly, enhancing safety protocols and optimizing workflows. Guarding against safety hazards is crucial in these environments, where real-time communication can alert staff about potential risks. Streamlined Inventory Management and Employee TrainingReal-time tracking facilitated by 5G and IoT enhances the accuracy of product availability, allowing businesses to optimize stock levels effectively. Additionally, comprehensive employee training on safety protocols and new technologies is essential for maximizing the benefits of these advancements and maintaining a secure workplace. Advanced Security MeasuresWith the adoption of 5G technology, integrating advanced surveillance systems and smart access control solutions becomes imperative. High-definition video streaming and biometric scanning not only protect against theft but also enhance operational safety, ensuring that only authorized personnel access sensitive areas. Concluding ThoughtsImplementing 5G in warehouse operations is vital for future-proofing businesses against evolving market demands. By fostering a culture of adaptability and continuous learning among employees, organizations can leverage innovative technologies such as AI and predictive analytics to enhance efficiency and maintain competitiveness in the global supply chain landscape. The future of warehouse management is bright, with the integration of 5G technology setting the stage for unprecedented operational capabilities. -

Achieving End to End Supply Chain Visibility: A Comprehensive Guide

Real-time data access enables informed strategies and optimized operations.- Risk Management: Enhanced visibility helps businesses identify and mitigate risks, reducing exposure significantly.- Customer Relationship Strengthening: Transparency fosters trust; when customers can track orders, they are more satisfied.- Operational Efficiency: Automation in processes leads to cost reductions and streamlined workflows. Tools and Technologies for Enhanced VisibilityVarious technologies improve supply chain visibility, including IoT devices, blockchain, and data analytics. These tools provide real-time insights into product conditions and locations, leading to better inventory management. Additionally, data visualization techniques help transform complex metrics into actionable insights, further supporting informed decision-making. Implementing End-to-End Supply Chain Visibility1. Assess Current Supply Chain State: Map out current processes to identify gaps in visibility and reporting.2. Establish KPIs: Define clear performance metrics to measure progress and success.3. Deploy Technology: Implement solutions such as IoT and blockchain to enhance tracking and data sharing across the supply chain.4. Foster Collaboration: Improve stakeholder communication and establish joint problem-solving initiatives for enhanced responsiveness.5. Continuous Monitoring: Utilize analytics tools for ongoing performance evaluation against established KPIs. Future Trends in Supply Chain VisibilityLooking ahead, advancements in AI and data analytics will drive predictive capabilities in supply chain visibility. Moreover, a growing focus on sustainability will prompt companies to assess their supply chains' environmental impact, aligning practices with consumer demand for transparency. ConclusionIn a rapidly changing market, achieving end-to-end supply chain visibility is more than a competitive advantage; it's foundational for business sustainability and growth. By leveraging advanced technologies and fostering collaborative relationships, organizations can create a resilient supply chain that not only meets customer demands but thrives in the face of challenges. -

The Green Advantage: Sustainable Supply Chains with Tech

Integrating Technology for Sustainable Practices in Supply ChainsIn today's rapidly evolving business landscape, integrating technology into supply chain management is essential for promoting sustainable practices. Innovations such as data analytics, the Internet of Things (IoT), and blockchain are revolutionizing the way companies operate, paving the way for improved efficiency, reduced waste, and enhanced transparency. Harnessing Data AnalyticsData analytics empowers businesses to streamline their operations by identifying trends and patterns that inform inventory management and demand forecasting. With predictive analytics, companies can increase forecasting accuracy by 50%, minimizing the risks associated with overstocking and stockouts. Real-time data monitoring solidifies this process, ensuring continuous improvement in supply chain efficiency. Internet of Things (IoT) in LogisticsThe IoT connects devices and sensors, allowing companies to monitor logistics operations closely. This technology optimizes delivery routes and reduces fuel consumption, aligning with stringent environmental regulations. Reports indicate that adopting IoT in logistics can reduce fuel consumption by 10-20%, bridging the gap between operational efficiency and sustainability. Enhancing Transparency with BlockchainModern technology enhances transparency in green supply chains, with blockchain leading the way. It allows for the tracing of products from origin to end-user, fostering trust and accountability among consumers. Companies employing software solutions to aggregate data across supply chain stages can monitor product journeys in real time, further promoting transparency and quality control. Importance of TraceabilityTraceability in supply chains is vital for identifying inefficiencies and minimizing environmental impacts. Consumers' preferences for companies committed to transparency are leading organizations to adopt such practices, creating competitive pressure in the industry. Establishing standards for transparency will help formalize companies' commitments to sustainability. Collaboration and Circular EconomyThe transition to a circular economy emphasizes resource longevity and reusability. Businesses cooperating across sectors to tackle challenges such as waste management significantly boosts sustainable initiatives. Notable examples, like Unilever's pledge for recyclable packaging, highlight the importance of embedding circular principles in supply chains. Measuring Sustainability MetricsEffective measurement of sustainability metrics—like carbon emissions and waste management—can highlight a company's commitment to eco-friendliness. Advanced analytics tools facilitate real-time monitoring and data collection, helping organizations track and visualize their sustainability efforts. Future TrendsLooking to the future, expect the integration of Artificial Intelligence in supply chains to boost predictive capabilities and further enhance sustainability practices. Companies will increasingly focus on reducing their carbon footprints and aligning with consumer demand for green products, ensuring long-term competitiveness in an eco-conscious market.By adopting these technologies and practices, businesses not only fulfill their sustainability goals but also enjoy improved operational efficiencies and increased consumer trust. The future of sustainable supply chains lies in innovation, transparency, and collaboration across industries. For those committed to sustainability, staying ahead of these trends is not just advantageous—it's essential for survival in today's conscious marketplace. -

AI for automating invoice processing

Converts physical documents into digital formats, automating data entry.- Natural Language Processing (NLP): Helps understand unstructured data within invoices, improving context comprehension.These technologies work together to elevate accuracy in data extraction, achieving near-perfect results and facilitating seamless financial workflows. Implementation StrategiesTo reap the benefits of AI, businesses should begin with a thorough audit of their current systems. This involves identifying bottlenecks and aligning stakeholders across finance, operations, and IT. Alongside system changes, investing in employee training is vital to ensure staff can effectively utilize these new tools, combining human oversight with AI capabilities. Cost ConsiderationsWhile the initial investment in AI solutions may appear steep, the long-term savings often justify the expense. Companies report a considerable return on investment (ROI) within the first year through decreased labor costs and efficiency improvements. A comprehensive cost analysis helps businesses understand the full benefits of adopting AI technologies. Data Security Handling sensitive financial information necessitates robust security protocols and compliance with regulations such as GDPR. Implementing measures such as encryption and access controls is imperative to safeguard against data breaches. Future TrendsThe future of AI in invoice processing is bright, with advancements like predictive analytics and blockchain technology on the horizon. Predictive analytics can optimize budget allocations based on historical data, while blockchain offers enhanced security and transaction transparency. Real-World ApplicationsAI in invoice processing presents various real-world applications, including:1. Streamlining Data Entry: Reducing manual efforts through automated data extraction.2. Enhancing Fraud Detection: Utilizing machine learning to identify anomalies.3. Automating Approval Workflows: Eliminating bottlenecks with AI-routing systems.4. Facilitating Compliance and Audit Trails: Maintaining regulatory compliance with detailed audit documentation.As companies continue to embrace AI to streamline their invoice processing, improved accuracy, cost savings, and enhanced supplier relationships will be key outcomes, ensuring a competitive edge in today’s market landscape. -

AI for Predictive Warehouse Operations and Layout Optimization

The Role of Predictive Analytics in Warehouse Operations Understanding Predictive Analytics in Warehouse ManagementPredictive analytics plays a pivotal role in optimizing warehouse management. By utilizing historical data and statistical algorithms, it forecasts future outcomes, focusing on inventory levels and demand fluctuations. Businesses that leverage predictive analytics can improve inventory turnover by up to 40%, reducing costs and enhancing customer satisfaction.As data complexity increases, advanced algorithms like machine learning make it easier to analyze vast datasets, uncovering hidden patterns. This technology aids in making warehouses more sustainable and efficient by enabling proactive decision-making, essential for the fast-paced market. Applications of Predictive Analytics in Operational EfficiencyPredictive analytics has diverse applications, significantly improving operational efficiency. By anticipating seasonal demand changes, warehouses can adjust resources, such as hiring temporary staff for peak periods. Moreover, it minimizes risks associated with overstocking or stockouts, as highlighted by a logistics provider that reduced excess inventory by 25% through predictive forecasting. Enhancing Layout Optimization through Predictive InsightsUsing predictive analytics for layout optimization is vital for streamlining operations. It allows warehouses to evaluate the best placement for goods based on real-time data, leading to reduced pick times and improved order fulfillment efficiency. Challenges in Implementing Predictive AnalyticsDespite its advantages, organizations face challenges in implementing predictive analytics, primarily data quality and skilled personnel. With accurate data input and the right talent, companies can overcome these hurdles, maximizing the benefits of analytics in their operations. Future Trends in Predictive AnalyticsThe future of predictive analytics in warehousing is bright, with AI and machine learning poised to drive more precise predictions and automated decision-making. Companies embracing IoT can gather real-time data, enhancing operational insights. Early adopters of these trends are likely to maintain a competitive edge in terms of efficiency and customer responsiveness. Optimizing Layout for Increased Operational EfficiencyAssessing current warehouse layouts is crucial in enhancing operational efficiency. Through evaluation and tools like heat maps, organizations can identify bottlenecks and implement actionable layout changes for smoother workflows. Implementing Data-Driven Design AdjustmentsOnce evaluations are completed, utilizing data-driven design adjustments, including AI tools, allows warehouses to forecast future needs and optimize storage locations effectively. Incorporating feedback loops ensures continual refinement and alignment with operational demands. Integrating Automation and TechnologyModernizing with automation and advanced technologies is vital for efficient layout and operation. Warehouses that adopt automated guided vehicles (AGVs) achieve significant throughput increases and lower manual labor costs. Ensuring Continuous Improvement and FlexibilityTo stay competitive, warehouses must embrace continuous improvement and flexibility in layout designs. Regular reviews aligned with market feedback will allow organizations to maintain efficiency and address inefficiencies swiftly.In summary, predictive analytics is transforming warehouse operations. By understanding its applications, overcoming challenges, and embracing future trends, organizations can enhance efficiency, adapt to market changes, and remain competitive in the logistics sector. -

Natural language processing for analyzing customer service chat logs in logistics

Optimizing Customer Service in Logistics with Natural Language Processing (NLP) What is Natural Language Processing?Natural Language Processing (NLP) represents a revolutionary facet of artificial intelligence, empowering systems to interpret, generate, and respond to human language meaningfully. With advancements in machine learning, NLP enhances customer service by analyzing chat logs and uncovering insights that can significantly improve engagement, especially in the logistics sector. The Impact of NLP in LogisticsNLP helps logistics companies streamline customer interactions, elevate satisfaction rates, and enhance service delivery by automating and categorizing inquiries. Research highlights the potential of NLP to boost response efficiency by as much as 30%, while sentiment analysis can reveal customer emotions, shaping tailored responses that foster loyalty. Machine Learning’s Role in NLPAt the heart of modern NLP applications lies machine learning. These algorithms learn from extensive datasets, enabling companies to identify recurring inquiries and optimize service processes. Effective categorization and trend recognition empower logistics firms to make data-driven strategic decisions. Key Benefits of NLP in Customer ServiceImplementing NLP not only automates responses but also provides actionable insights that lead to strategic improvements. By analyzing interactions, logistics organizations can enhance their training programs, ensuring staff are equipped to handle emerging customer needs. The result is a more efficient workflow, a personalized customer experience, and ultimately, increased satisfaction. Navigating Challenges in NLP ImplementationDespite its advantages, NLP implementation poses challenges, such as the unpredictability of human language. Businesses must find the right balance between automation and the human touch to maintain response quality. Continuous refinement of algorithms, coupled with a hybrid customer service model, helps navigate these challenges effectively. Future Trends and InnovationsThe future of NLP in logistics looks promising, with trends leaning towards deeper emotional recognition and contextual understanding. Technologies like augmented reality might converge with NLP, creating virtual assistants for real-time updates and personalized recommendations. As NLP models evolve to recognize slang and dialects, logistics companies that adopt these advancements will likely gain a competitive advantage. Enhancing Customer Experience through Data InsightsUtilizing chat log analysis equips logistic firms with critical customer insights. Identifying recurring themes, such as shipment delays, allows companies to proactively address issues and refine their communication strategies. Real-time analytics can dynamically adjust service protocols based on current trends, further enhancing customer interactions. ConclusionIntegrating Natural Language Processing into customer service operations within logistics not only boosts efficiency but also generates actionable insights that lead to continuous improvement. By harnessing the power of NLP and machine learning, logistics firms can create a customer-centric experience that not only meets but exceeds expectations. Embrace the future of customer service today by optimizing your operations with these cutting-edge technologies. -

Real Time Visibility for Perishable Goods Supply Chains

A Key to Success OverviewIn today's fast-paced market, real-time visibility within supply chains has become essential for businesses handling perishable goods. This capability not only aids in tracking goods’ locations but also assures their conditions throughout the supply chain. When implemented effectively, advanced tracking technologies can significantly reduce risks related to spoilage, theft, and logistical delays. What is Real-Time Visibility?Real-time visibility allows stakeholders to monitor products continuously, addressing challenges promptly. Businesses that leverage modern tracking systems, such as RFID (Radio Frequency Identification), IoT (Internet of Things), and GPS, can improve operational efficiency. According to the Council of Supply Chain Management Professionals, companies employing these technologies have experienced up to a 30% reduction in waste due to spoilage. Technologies Behind Real-Time TrackingAdvanced tracking tools, including IoT devices and RFID systems, enable real-time condition monitoring for perishable items. This includes crucial factors such as temperature and humidity, ensuring compliance with safety regulations. The integration of these technologies enhances communication among suppliers, distributors, and retailers while safeguarding product integrity through proactive alerts and data-sharing capabilities via cloud platforms. Impact on Waste ReductionThe ability to monitor inventory in real-time can lead to substantial reductions in food waste. The Food and Agriculture Organization estimates that a third of global food production goes to waste—often during transportation and storage. Real-time tracking can fine-tune inventories and optimize delivery routes, with businesses reporting spoilage reductions of up to 50%. Challenges to ImplementationDespite the significant benefits of real-time visibility, challenges exist, including:- High Initial Costs: Smaller businesses may find the financial investment daunting.- Integration Complexities: Merging new technologies with legacy systems can be problematic.- Data Privacy Concerns: Increased data collection raises security issues that must be diligently addressed. Successful Case StudiesSeveral companies have demonstrated the advantages of implementing real-time visibility systems. For example, a leading grocery chain employing IoT sensors experienced a 25% decrease in spoilage, while a dairy producer utilizing RFID for tracking maintained the required temperature conditions throughout transport, enhancing customer satisfaction and reducing waste. The Future of Visibility in Supply ChainsLooking ahead, trends such as artificial intelligence (AI) and blockchain technology are poised to revolutionize supply chains further. AI can provide predictive analytics, enabling proactive adjustments to operations, while blockchain enhances transparency and security throughout the supply chain. Companies that adopt these technologies are likely to gain a competitive edge as consumer demand for transparency and sustainable practices continues to grow. ConclusionInvesting in real-time visibility and tracking technologies is no longer just a technological improvement—it's becoming a necessity for businesses handling perishable goods. By understanding the challenges and embracing advanced solutions, organizations can significantly mitigate risks, enhance operational efficiency, and position themselves competitively for future growth. For a deeper understanding of real-time visibility’s benefits, explore our comprehensive guide to tracking innovations in supply chains. -

The Importance of Change Management in Supply Chain Tech Adoption

Integrating Technology for Enhanced Supply Chain ManagementIn the rapidly evolving landscape of supply chain management, seamlessly integrating technology into existing processes is not just a trend; it’s a necessity. This comprehensive guide outlines effective strategies for assessing current workflows, identifying suitable technological solutions, and optimizing employee engagement to ensure a successful transition. Assess Current ProcessesA thorough assessment of existing supply chain processes is the first step in technology integration. Mapping workflows helps identify inefficiencies, as highlighted by McKinsey's study where 60% of organizations emphasized the importance of process visibility. This phase not only reveals current challenges, but sets the foundation for choosing the right technology, aided by analytical tools that combine qualitative and quantitative insights. Identify Suitable Technology SolutionsPost-assessment, selecting the right technology—be it AI-driven analytics, IoT devices, or blockchain solutions—is crucial. Gartner's findings indicate that cloud-based supply chain solutions can reduce costs by up to 30%. Research various technologies tailored to your organization's specific needs to optimize operational efficiencies. Engage StakeholdersUtilizing stakeholder involvement is imperative for a smooth transition. Team members, management, and external partners can offer invaluable insights that facilitate the adoption process. Engaging these stakeholders through forums or workshops ensures alignment and reduces resistance, fostering an inclusive environment where feedback is encouraged. Measure ImpactPost-integration, it is vital to measure the effectiveness of the newly adopted technology. Establishing Key Performance Indicators (KPIs) provides actionable data on lead times, inventory accuracy, and overall cost savings. Continuous tracking of these metrics not only enhances operational efficiency—by an estimated 15%—but also allows organizations to make necessary adjustments. Enhance Workforce EngagementTo bolster employee engagement during transitions, effective communication and inclusive training programs are essential. Employees appreciate transparency surrounding changes impacting their roles. By implementing tailored training approaches, organizations increase confidence levels, which leads to smoother technology adoption. Address Resistance to ChangeUnderstanding employee resistance—often rooted in fear or uncertainty—plays a crucial role in successful change management. Leaders must proactively address these concerns, fostering an environment of open communication and support. Clarity in communication regarding the need for change diminishes resistance and empowers employees to embrace new processes. Leadership and Change ManagementEffective leadership is instrumental in guiding organizations through transitions. Leaders who exemplify commitment and provide a clear vision see increased employee engagement rates. By encouraging feedback and collaboration, leaders can cultivate a culture of ownership that further supports successful change initiatives. Continuous ImprovementFinally, iterative processes and continuous feedback loops ensure organizations remain agile. Regular reviews and performance assessments allow for real-time adjustments, driving ongoing improvement in technology integration. Recognizing employee adaptability reinforces positive behaviors, fostering a collaborative atmosphere essential for long-term success.In conclusion, integrating technology into supply chain management is a multifaceted process that requires careful assessment, stakeholder engagement, and ongoing evaluation. By committing to these strategies, organizations can enhance operational efficiency, employee engagement, and overall performance, navigating the complexities of today's supply chain landscape with confidence. -

Navigating Vendor Selection for Supply Chain Technology

A Comprehensive GuideUnderstanding and optimizing your supply chain is crucial for achieving operational efficiency and meeting customer demands. This guide walks you through essential steps in identifying and addressing your supply chain needs, including assessing challenges, defining technology requirements, engaging stakeholders, and budgeting effectively. Assessing Current Supply Chain ChallengesBegin by identifying existing challenges within your supply chain, such as delivery delays, inconsistent material quality, and poor inventory management. Collect data through surveys, interviews, and performance reports to understand these issues better. According to the Institute for Supply Management, 70% of companies experience supply chain disruptions, highlighting the need for thorough evaluations. Defining Specific Technology RequirementsOnce you've assessed challenges, define your technology needs. Are you looking for real-time tracking or enhanced analytics capabilities? By clearly outlining your technological requirements, you not only simplify vendor selection but also ensure that identified solutions align with your operational goals. Engaging Stakeholders for Comprehensive InsightsEngaging internal stakeholders can greatly enhance your understanding of supply chain needs. Collaboration among different departments—such as procurement, logistics, and IT—ensures a well-rounded view of requirements. Workshops and discussions promote open communication, enhancing the overall decision-making process. Budget Considerations and Financial PlanningBudgeting for supply chain technology involves considering initial costs and ongoing expenses, including maintenance and training. Conduct a cost-benefit analysis to better understand the long-term implications of your technology choices. Research shows that companies implementing advanced technologies see a reduction in costs of up to 25% over five years, making it essential to explore budgetary options and funding incentives. Conducting Market ResearchThorough market research is critical to understanding your target demographics and customer preferences. Utilize qualitative and quantitative methods to gather insights, analyze competitors' performance, and collect secondary data for informed vendor selection. Evaluating Vendor Capabilities and CompatibilityWhen evaluating potential vendors, assess their technology offerings and past experience in your industry. Look for scalability, compatibility with existing systems, and robust technical support. Transparency in pricing and financial stability are also key factors in making informed decisions. Involving Stakeholders in the Decision-Making ProcessIdentify and engage key stakeholders early in the process, facilitating collaboration through regular check-ins and workshops. A collective approach to evaluating vendors can ensure comprehensive reviews and ultimately lead to better technology choices. Negotiating Contracts and Finalizing SelectionContracts are vital in establishing clear expectations and responsibilities. Make sure to outline deliverables, timelines, and dispute resolution methods. Enter negotiations with a clear strategy and necessary data to support your needs. Post-Contract Monitoring and Relationship ManagementAfter finalizing your vendor selection, maintain an ongoing relationship by monitoring performance against established criteria. Regular communication fosters collaboration and helps align objectives. Embracing Future TrendsStay informed about the evolving landscape of supply chain agreements, including the impact of technology and growing sustainability requirements. Companies that adapt to these trends position themselves as leaders in supply chain management.By following these steps, businesses can effectively identify their supply chain needs, leading to improved operations and enhanced customer satisfaction. -

Automating Creative Tasks: Generative AI in Supply Chain Marketing Campaigns

Generative AI enables companies to craft tailored messages rapidly for various consumer segments, boosting conversion rates.- Improved Engagement: Personalized marketing strategies, driven by data insights provided by AI, significantly enhance customer interaction.- Cost Efficiency: Automation of creative processes leads to reduced production costs while maintaining quality.- Data-Driven Targeting: AI provides real-time analytics, allowing marketers to adjust strategies swiftly based on audience behavior. Challenges and ConsiderationsDespite the advantages, integrating generative AI requires a thoughtful approach. Marketers must balance automation with a human touch to maintain brand authenticity. Data privacy is another critical concern; adhering to regulations like GDPR is imperative when handling consumer data. Enhanced Content Creation with AIAI is not just a tool for generating marketing materials; it's a strategic partner in crafting effective content strategies. By analyzing consumer preferences, AI aids in optimizing performance across platforms, improving engagement, and facilitating faster production cycles. Tools like Jasper and Copy.ai exemplify how businesses can streamline content creation, enabling marketers to focus more on strategic initiatives. Driving Personalization to New HeightsGenerative AI excels in tailoring marketing messages to individual consumer preferences, which is proven to increase customer loyalty and boost sales. With the ability to analyze purchasing behaviors, AI paves the way for hyper-targeted marketing efforts. Predictive modeling further enhances this personalization, allowing brands to anticipate customer needs and shape proactive marketing strategies. Measurement and AnalyticsTo truly harness the power of AI in marketing, businesses must establish clear Key Performance Indicators (KPIs). Metrics such as engagement rates, conversion rates, and customer acquisition costs become crucial in assessing the effectiveness of campaigns. AI analytics facilitates real-time monitoring, allowing for swift adjustments to optimize performance and improve ROI. Future TrendsAs the field of AI continues to evolve, businesses that adapt will gain a competitive edge. Innovations in natural language processing and machine learning are setting the stage for even more insightful and contextually aware marketing strategies. Brands are poised to leverage these advancements, ensuring they meet changing consumer expectations effectively.In summary, generative AI isn't just a technological trend; it’s a vital component for organizations aiming to excel in the competitive marketing landscape. By embracing AI, businesses can streamline processes, enhance personalization, and drive meaningful engagement with their audiences. -

Scaling Your Business: Adaptable Supply Chain Technology for Growth

Quickly shift operations based on consumer preferences.- Cost efficiency: Optimize resources and reduce unnecessary expenses.- Enhanced customer satisfaction: Ensure timely deliveries and meet customer expectations.- Improved risk management: Navigate uncertainties with a robust supply chain strategy. Implementing Flexible Supply Chain StrategiesTo realize these benefits, organizations should embrace advanced technologies, like artificial intelligence and machine learning. These tools enhance decision-making capabilities by analyzing vast amounts of data and identifying trends, resulting in better demand forecasting and supply chain performance. Collaboration among departments and suppliers is crucial for seamless integration, ensuring efficient communication and operational effectiveness. Key Technologies Transforming Supply Chains 1. Blockchain TechnologyUtilizing a decentralized ledger system, blockchain increases transparency and reduces fraud risk in supply chains. Major companies are already implementing these solutions to streamline operations and build customer trust. 2. Artificial Intelligence (AI)AI enhances demand forecasting accuracy by processing historical data swiftly. Companies employing AI have reportedly seen a forecast accuracy improvement of up to 50%, leading to better inventory management and increased profits. 3. Internet of Things (IoT)IoT devices optimize logistics by tracking goods in real time, allowing businesses to proactively manage potential disruptions and improve overall operational resilience. 4. Cloud ComputingCloud technology provides unparalleled flexibility, making it easier for organizations to scale operations based on market needs. It also fosters better collaboration among supply chain partners. 5. Robotic Process Automation (RPA)RPA simplifies repetitive tasks in supply chain management, allowing human resources to focus on strategic activities, ultimately leading to significant cost savings. 6. Advanced AnalyticsIncorporating advanced analytics can drive informed decision-making and resource allocation, enhancing supply chain performance by 10-15%. 7. Sustainability TechnologiesWith growing consumer demand for environmentally friendly practices, sustainability technologies help companies minimize their carbon footprint and comply with regulations while improving their brand reputation. Strategies for Implementing Adaptable Supply Chain Solutions1. Evaluate Supply Chain Needs: Assess workflows, technology infrastructure, and operational bottlenecks.2. Leverage Technology: Embrace cloud computing and advanced analytics for flexibility.3. Maintain Strong Supplier Relationships: Foster open communication and strategic partnerships to enhance resilience.4. Continuous Monitoring: Regularly track performance metrics to identify areas for improvement.By understanding and investing in flexible supply chain solutions, businesses not only enhance their operational efficiency but also position themselves for long-term success. The ability to respond promptly to changing market conditions can significantly impact customer satisfaction and overall business performance. Stay ahead of the curve by adopting adaptable supply chain technologies and strategies that foster a culture of innovation and continuous improvement. -

Supply Chain Traceability for Regulatory Compliance

A Comprehensive Guide Introduction to Supply Chain TraceabilitySupply chain traceability is the ability to monitor and track products from their origin to the final consumer. This process captures vital data about a product, enhancing transparency, accountability, and quality control within operations. By implementing sophisticated tracking mechanisms, such as blockchain and RFID technology, businesses can ensure authenticity and swiftly address issues like recalls and contamination. Importance of Regulatory ComplianceRegulatory compliance is paramount in supply chain management, especially in industries such as food, pharmaceuticals, and technology. Governments require adherence to rigorous documentation standards to ensure public safety and environmental protection. Companies that invest in traceability systems not only meet legal standards but also enhance their reputation as responsible entities in the marketplace. Technological Innovations Enhancing TraceabilityThe integration of advanced technologies plays a crucial role in improving traceability:- Blockchain Technology: Provides secure, transparent, and immutable data storage, fostering trust among stakeholders.- RFID Tags: Enable real-time tracking of goods, enhancing inventory management.- IoT Devices: Facilitate continuous monitoring of product conditions to maintain quality.- Data Analytics: Offer predictive insights that improve decision-making processes. Benefits of Enhanced TraceabilityEnhanced traceability yields multiple benefits, including:- Consumer Trust: Allowing customers to verify product sourcing fosters loyalty and transparency.- Operational Efficiency: Businesses can leverage traceability data to optimize their supply chain processes.- Quick Incident Response: Organizations can promptly address issues, minimizing health risks and financial losses. Research indicates that enhanced traceability systems can lead to significant cost savings and increased operational efficiencies, solidifying a company's market reputation. Real-World Applications of TraceabilityVarious industries benefit from traceability, particularly the food sector. For instance, companies like Walmart utilize blockchain to trace food products from farm to store, ensuring quick responses to food safety concerns. Pharmaceutical industries also rely on traceability to prevent counterfeit products, enhancing consumer safety. Challenges in Implementing Traceability SystemsWhile the advantages are clear, implementing traceability systems poses challenges. Key obstacles include:- Cost: The financial burden of adopting new technologies can be daunting, especially for small to medium-sized enterprises.- Data Integrity: Establishing robust mechanisms to protect data accuracy is essential.- Collaboration: Creating seamless communication among supply chain stakeholders is necessary for effective implementation. Future Trends in Supply Chain TraceabilityLooking ahead, the adoption of AI-driven analytics, IoT integration, and a heightened focus on sustainability will shape the future of supply chain traceability. Companies must adapt to evolving regulatory requirements and consumer expectations by investing in these technologies to maintain a competitive edge. ConclusionIn an increasingly complex supply chain landscape, traceability is not merely a compliance tool but a vital component of operational resilience. By embracing technology and fostering transparency, businesses can enhance consumer confidence, improve efficiency, and support sustainable practices, ultimately driving long-term success. -

Human Robot Collaboration: A New Era in Logistics

Transforming the Future of Supply Chain OperationsHuman-Robot Collaboration (HRC) is revolutionizing the logistics sector by effectively integrating innovative robotic systems with human workers. This collaboration enhances operational efficiency across various logistics processes, including warehousing and product delivery. Businesses implementing HRC have reportedly witnessed up to a 30% improvement in efficiency compared to traditional logistics methods, thanks to advanced technologies including AI, machine learning, and real-time data analytics. Understanding HRC in LogisticsHRC aims to streamline logistical operations by capitalizing on the strengths of both humans and robots. Robots can perform repetitive tasks while adapting to real-time changes based on human feedback, leading to higher productivity. However, effective communication between human workers and robotic systems remains a challenge. It’s crucial that robots are equipped to understand and respond accurately to human actions to prevent workflow interruptions. Benefits of HRC Enhanced EfficiencyHRC optimizes logistics workflows, reducing picking errors by up to 30% and decreasing overall turnaround times. Robots efficiently manage routine tasks, allowing human employees to focus on more complex responsibilities. Improved SafetyRobots take on hazardous tasks, significantly lowering workplace injury rates. Collaborative robots, or cobots, come with safety features that enable safe interaction with human workers, thereby enhancing workplace safety. Data-Driven InsightsHRC generates valuable data that informs decision-making. Companies using data analytics can identify inefficiencies and improve supply chain performance, fostering competitiveness in the logistics industry. Scalability and FlexibilityHRC offers scalability by allowing companies to adjust robotic use according to business demand without extensive retraining. This adaptability helps operations respond quickly to market fluctuations and evolving customer needs. Challenges of Implementing HRCWhile the integration of robots into logistics provides numerous advantages, it also presents significant challenges. Technical limitations, such as insufficient sensory capabilities, can hinder operational efficiency. Additionally, the workforce may face a skills gap, as many employees lack the technical know-how to collaborate effectively with robotic systems.Safety concerns and mistrust of robots can impede acceptance. Comprehensive training programs are essential for ensuring that staff understand robotic operations and safety protocols, fostering trust and creating a safer working environment. The Future of HRC in LogisticsLooking ahead, the landscape of HRC in logistics promises exciting advancements. With AI and machine learning technologies advancing, robots are expected to become increasingly autonomous, capable of handling an expanded range of complex tasks. As logistics companies adopt these solutions, projected savings could reach up to $50 billion annually by 2030.Emerging technologies, like advanced sensors, enhance robots' capabilities, enabling them to navigate complex environments fluidly. The continued collaboration between humans and robots will not only reshape operational efficiency but also redefine workforce roles, leading to a need for new training and skill development. ConclusionIn conclusion, Human-Robot Collaboration in logistics presents significant opportunities and challenges. By understanding its foundational elements, benefits, and potential obstacles, organizations can strategically plan for implementation, ensuring a future where seamless and efficient logistics operations become the norm. As technology continues to evolve, those who adapt will undoubtedly gain a competitive edge in the ever-changing logistics landscape. -

IoT for monitoring energy consumption in warehouses

The Role of IoT Sensors in Energy ManagementIoT sensors are indispensable for monitoring critical metrics such as temperature, humidity, and equipment efficiency. By providing real-time data, these sensors facilitate energy consumption reductions of up to 30%. Understanding energy patterns helps warehouses identify inefficiencies and targets for intervention, enhancing both cost savings and sustainability initiatives. Data Analytics: Transforming Insights into ActionOnce data is gathered by IoT devices, advanced analytics platforms process this information to reveal trends and anomalies. Facilities can strategically adjust operations based on historical data and future forecasts, enabling informed decisions that optimize energy use and reduce waste. Real-Time Monitoring and AlertsThe capacity for real-time monitoring allows warehouses to receive alerts regarding energy spikes. Immediate notifications empower facility managers to address unforeseen issues, such as equipment malfunctions, thus maintaining tighter control over energy expenditures and long-term strategies. Successful IoT Implementation Case Studies Real-world examples highlight the effectiveness of IoT in energy management. A large logistics company reported a 25% reduction in energy costs within the first year of integrating IoT technologies, while a retail giant optimized their HVAC systems, significantly reducing cooling costs during non-peak hours. These cases demonstrate the potential ROI of adopting IoT solutions. Future Trends in IoT and Energy EfficiencyThe landscape of IoT in warehouse energy management continues to evolve, with trends toward enhanced automation and machine learning. These advancements promise even more accurate energy consumption predictions and stronger integration with renewable energy sources—critical for organizations aiming to meet sustainability goals and stay competitive. Conclusion: Embracing IoT for Sustained Energy SavingsIntegrating IoT technologies into warehouse environments paves the way for effective energy management. By leveraging real-time data, proactive analytics, and innovative automation, warehouses can achieve significant cost reductions and contribute to sustainability efforts. Organizations embracing IoT solutions are better equipped to navigate the rapidly evolving industry landscape and drive operational excellence. Benefits of Real-Time Energy MonitoringReal-time energy monitoring bolsters operational efficiency by identifying patterns indicative of inefficiencies, allowing informed adjustments that minimize expenditures. Additionally, it aids in the early detection of anomalies, potentially saving substantial costs by preventing equipment failures.As the commitment to environmental sustainability grows, so does the importance of tracking and managing energy efficiently through innovative technology. This integration not only enhances operational capabilities but aligns with consumer-driven demand for eco-friendliness.---By adopting IoT solutions, warehouses can not only streamline operations but promote a more sustainable future, ultimately enhancing both efficiency and profitability. Explore how IoT transformation can benefit your organization today! -

Supply Chain Visibility for Returns Logistics

The Importance of Supply Chain Visibility in Returns LogisticsIn today's fast-paced e-commerce environment, the effectiveness of returns logistics can significantly impact a company's bottom line and customer satisfaction. Supply Chain Visibility (SCV) is essential for tracking transactions and product conditions throughout the returns process. Organizations leveraging robust SCV can reduce operational costs by up to 15% and enhance processing efficiency by 25%, as confirmed by recent insights from the Warehousing Education and Research Council (WERC). Key ChallengesHowever, many companies face obstacles in achieving effective supply chain visibility. Fragmented tracking systems and inconsistent data across platforms lead to inaccuracies that complicate the returns process. A survey by the Council of Supply Chain Management Professionals (CSCMP) revealed that nearly 60% of professionals struggle with data access, hindering the ability to maintain real-time visibility. Best Practices for Enhanced VisibilityTo overcome these challenges, businesses must adopt best practices such as implementing centralized returns management systems that integrate data from various sources. Investments in technologies like RFID and IoT devices can significantly improve tracking accuracy, offering granular visibility into returned products. Automating these processes reduces manual errors and enhances the customer experience with real-time updates on return status. The Role of Advanced TechnologiesTechnologies like Real-Time Tracking, Data Analytics, and Collaborative Platforms are game-changers in returns logistics. Utilizing RFID can minimize misplaced shipments by 25%, while data analytics helps businesses forecast return rates and refine inventory practices, often resulting in a 30% reduction in processing time. Collaborating through integrated platforms ensures seamless communication among stakeholders, enhancing overall efficiency. Building a Robust Returns Management StrategyA well-designed returns management strategy enhances brand loyalty and optimizes customer satisfaction. Clear return policies and technology integration streamline operations while reducing costs. Companies that invest in articulate policies and supportive tech tools tend to see significant improvements in returns processing.Challenges like managing reverse logistics and preventing fraud must also be addressed. Establishing inspection protocols for returned products and robust verification processes can help preserve profitability. Future Trends in Returns ManagementThe landscape of returns logistics is evolving, with AI and machine learning set to play essential roles in predicting return rates and addressing common return issues proactively. Sustainability trends are also emerging, with brands focusing on environmentally friendly practices, fostering a “circular economy” where returns are reintegrated into supply chains. Measuring SuccessTo assess success in returns logistics, organizations should establish Key Performance Indicators (KPIs) focused on processing times, return costs, and customer satisfaction. Utilizing advanced tracking systems improves accuracy and enhances customer experiences, with 72% of customers preferring brands that facilitate easy returns. Regular customer feedback analysis helps companies refine their return strategies. Staying ahead of industry trends ensures businesses adapt to common return reasons, fortifying brand loyalty and customer satisfaction.Overall, enhancing supply chain visibility in returns logistics is not only about operational efficiency—it's about creating a seamless and satisfying experience for customers, ultimately driving sustained business success. -

AI for predictive maintenance of automated storage systems