物流能力計画におけるデジタルツインの利点

Optimizing Resource Allocation and Route Planning

Efficient Resource Management Strategies

Effective resource allocation is crucial for any organization's success. By strategically managing resources, companies can maximize their output while minimizing waste and maximizing profitability. This involves a multifaceted approach, encompassing careful planning, consistent monitoring, and a proactive approach to problem-solving. Optimizing resource allocation requires a clear understanding of the organization's needs and the available resources, allowing for the most efficient use of each asset.

Understanding the interplay between different departments and projects is key to effective resource management. A holistic view of the entire operation, rather than focusing on individual departments in isolation, allows for a more comprehensive and accurate assessment of resource needs. This integrated approach can lead to significant improvements in overall efficiency and productivity. This means ensuring all departments have the necessary resources to achieve their objectives without unnecessary duplication or overlap.

Impact on Organizational Performance

Optimizing resource allocation directly impacts an organization's bottom line. Improved efficiency leads to reduced costs and increased profitability. This is achieved by eliminating bottlenecks, streamlining processes, and ensuring that resources are utilized in the most productive manner. By effectively managing resources, businesses can allocate their capital and human resources to projects that provide the highest return on investment.

Furthermore, effective resource management fosters a more productive and engaged workforce. When employees feel supported and equipped with the necessary resources to succeed, they are more likely to be motivated and deliver high-quality work. This positive impact on employee morale contributes to a more positive work environment and ultimately, boosts overall organizational performance. A well-managed resource allocation strategy not only improves financial outcomes but also strengthens the company culture.

Careful consideration of resource allocation strategies can significantly improve project timelines and reduce delays. By proactively addressing potential resource constraints, organizations can mitigate risks and ensure projects are completed on schedule and within budget. This, in turn, builds trust with stakeholders and enhances the organization's reputation.

Efficient resource allocation contributes to a more sustainable business model. By minimizing waste and optimizing utilization, organizations can reduce their environmental footprint and contribute to a more responsible approach to business operations. This is increasingly important in today's environmentally conscious world.

Ultimately, optimizing resource allocation is a continuous process. Regular evaluation and adjustments are necessary to adapt to changing circumstances and maintain optimal performance. By embracing a dynamic approach, organizations can ensure they are always maximizing the value of their resources.

Predictive Maintenance and Enhanced Maintenance Scheduling

Predictive Maintenance Strategies

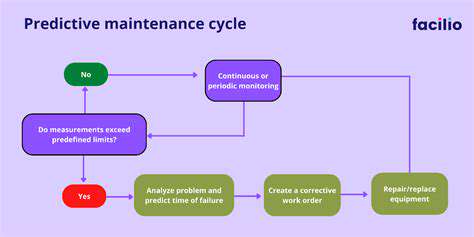

Predictive maintenance (PdM) is a proactive approach to maintenance that leverages data analysis to predict potential equipment failures before they occur. This approach significantly differs from reactive maintenance, which only addresses issues after a failure has already happened. By anticipating failures, PdM minimizes downtime, reduces repair costs, and extends the lifespan of equipment. This proactive strategy is crucial in today's manufacturing and industrial environments where operational efficiency and equipment reliability are paramount.

Various methods are employed in predictive maintenance. These include vibration analysis, monitoring of temperature and pressure fluctuations, and the use of sophisticated sensor technologies. Each method provides valuable insights into the health of equipment, enabling technicians to identify anomalies and potential failure points. Analyzing this data allows for the scheduling of maintenance activities well in advance, minimizing disruptions to production schedules.

Data Analytics in PdM

The core of predictive maintenance is data analytics. Data collected from various sources, such as sensors, operational logs, and historical maintenance records, is crucial for identifying patterns and trends indicative of potential equipment failures. Sophisticated algorithms and machine learning techniques are employed to analyze this data, enabling the identification of subtle anomalies that might otherwise go unnoticed.

This data-driven approach allows for the creation of predictive models that forecast the likelihood of equipment failure with a high degree of accuracy. This predictive capability is fundamental to PdM's ability to optimize maintenance schedules and minimize downtime. Real-time monitoring and analysis further enhance the efficacy of predictive maintenance.

Enhanced Operational Efficiency

Predictive maintenance significantly enhances operational efficiency by minimizing downtime and maximizing equipment uptime. By proactively addressing potential issues, organizations can avoid costly repairs and production disruptions. This results in a substantial reduction in maintenance costs and an increase in overall operational efficiency. Reduced downtime and optimized maintenance schedules translate directly into higher productivity and improved profitability.

The ability to predict failures allows for the scheduling of maintenance activities during periods of low production or minimal disruption. This avoids the necessity of unscheduled downtime, which can be extremely costly. Predictive maintenance also enables the optimization of resource allocation, focusing maintenance efforts on the most critical components and preventing unnecessary interventions.

Future Trends in PdM

The future of predictive maintenance is characterized by the increasing sophistication of data analysis techniques, the proliferation of connected devices and the integration of Artificial Intelligence (AI). These advancements promise to further refine predictive models, leading to even more accurate predictions and proactive maintenance strategies. The convergence of these technologies will enable even greater insights into equipment health, allowing for more precise maintenance scheduling and reduced downtime.

The integration of Internet of Things (IoT) devices and cloud-based platforms will facilitate real-time monitoring and analysis of equipment data. This real-time feedback will empower organizations to react swiftly to emerging issues, ensuring continuous operational efficiency. Furthermore, the use of AI and machine learning for predictive modelling is expected to become increasingly sophisticated, leading to more accurate and reliable predictions.