Wydajność dostawców: Poprawa oceny dzięki analizom napędzanym przez AI

Beyond the Numbers: Understanding the Context

While metrics are crucial for tracking progress and identifying areas for improvement, focusing solely on numbers can lead to a narrow and potentially misleading understanding of the underlying issues. A deeper dive into the context surrounding these metrics is essential for truly effective analysis. This involves considering the historical trends, external factors, and internal processes that may be influencing the results.

For instance, a sudden drop in sales figures might be attributed to a temporary economic downturn or a competitor's aggressive marketing campaign rather than internal issues. Understanding the broader context allows for a more nuanced interpretation of the data and helps avoid making hasty or inaccurate conclusions.

The Human Element: Recognizing the Impact of People

People are at the heart of any organization, and their motivations, skills, and experiences significantly impact performance. Ignoring the human element in your analysis can result in missing critical insights and opportunities for improvement. Consider the level of employee engagement, training opportunities, and the overall work environment.

Factors like job satisfaction, communication channels, and team dynamics all play crucial roles in determining output. Analyzing these elements can uncover hidden bottlenecks and suggest strategies for increasing productivity and efficiency, which often go beyond simply adjusting metrics.

Process Optimization: Identifying Systemic Issues

Often, the root cause of performance discrepancies lies within the organizational processes themselves. Inefficient workflows, outdated systems, or inadequate resources can significantly hinder progress, despite seemingly optimal metrics. A meticulous examination of these processes is crucial for identifying and addressing systemic issues.

Analyzing the steps involved in a particular task or project, identifying bottlenecks, and exploring alternative approaches can lead to significant improvements. Implementing process optimization strategies can often yield substantial gains in efficiency and productivity, even without major changes to the workforce or resources.

Future Forecasting: Anticipating Trends and Challenges

Looking beyond the present, understanding the potential future trends and challenges is vital for proactive decision-making. By analyzing historical patterns and external factors, organizations can anticipate potential obstacles and leverage opportunities before they arise. This involves understanding market shifts, technological advancements, and competitive pressures.

Proactive planning, informed by an understanding of the hidden factors influencing performance, allows for greater resilience and adaptability in the face of future challenges, ensuring sustained success. This forward-thinking approach, driven by a nuanced understanding of the factors beyond metrics, is essential for long-term growth and sustainability.

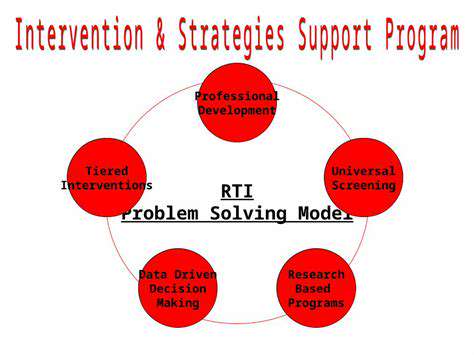

The Future of Supplier Performance: Data-Driven Decision Making

Predicting Supplier Performance

Accurate prediction of supplier performance is crucial for proactive risk management and strategic decision-making. By analyzing historical data, including delivery times, quality metrics, and communication patterns, businesses can identify potential issues before they escalate. This allows for the implementation of preventative measures and the mitigation of potential disruptions to supply chains. Predictive analytics tools can help identify suppliers who are likely to experience performance issues, enabling companies to proactively address these concerns.

Understanding the factors that drive supplier performance is essential to building effective predictive models. These factors can include internal operational efficiencies within the supplier's organization, external market conditions, and even geopolitical events. Analyzing these factors allows for a more comprehensive understanding of the potential risks and opportunities associated with each supplier relationship. This proactive approach to supplier relationship management ultimately leads to more resilient and adaptable supply chains.

Improving Supplier Collaboration

Enhanced communication and collaboration between suppliers and businesses are key to improving overall performance. Regular communication channels, including real-time data sharing and joint problem-solving sessions, foster transparency and trust. This, in turn, leads to more effective issue resolution and a smoother flow of goods and services. Improved collaboration allows for a more flexible and responsive supply chain.

Developing clear performance metrics and expectations from the outset helps both parties understand their roles and responsibilities. This shared understanding creates a framework for consistent performance and fosters a culture of accountability. Clear communication channels and a shared understanding of expectations are essential for successful long-term partnerships.

Leveraging Technology for Efficiency

Integrating technology into supplier relationships can streamline processes and improve efficiency. Digital platforms for tracking orders, managing inventory, and communicating with suppliers can significantly reduce administrative overhead. This allows businesses to focus on strategic initiatives and optimize resource allocation. Automated systems can facilitate faster order processing and reduce the potential for errors, leading to greater accuracy and efficiency.

Implementing advanced technologies, such as AI-powered solutions for predictive maintenance or machine learning models for quality control, can further enhance performance. This technological integration can lead to a significant improvement in supplier performance and reliability.

Sustainable Practices and Ethical Sourcing

Consumers are increasingly demanding sustainable and ethically sourced products. Companies are responding by integrating sustainability criteria into their supplier selection and performance evaluation processes. This includes assessing environmental impact, labor practices, and fair trade principles. Prioritizing sustainability and ethical sourcing not only addresses growing consumer expectations but also fosters a positive corporate image.

Implementing sustainable practices throughout the supply chain can reduce environmental impact and promote social responsibility. Suppliers who demonstrate a commitment to sustainability are often seen as more reliable and trustworthy partners.

The Role of Data Analysis in Supplier Performance

Data analysis plays a critical role in identifying key performance indicators (KPIs) and evaluating supplier performance. By tracking metrics such as delivery time, order accuracy, and quality control, companies can identify trends and patterns that indicate areas for improvement. This data-driven approach allows for targeted interventions and the development of customized strategies to enhance supplier capabilities. Comprehensive data analysis can reveal hidden issues and opportunities within a company's supply chain.

Utilizing data analytics tools to monitor supplier performance allows for early identification of potential problems, enabling proactive solutions. This proactive approach to supplier relationship management leads to a more robust and adaptable supply chain. Data-driven decision-making ultimately leads to improved supplier performance and a more resilient business model.

- Studia przypadku: Częste problemy zdrowotne psów i rozwiązania

- Jak przygotować swojego psa na zmiany pór roku

- Jak wybrać odpowiedni szelki dla swojego psa?

- Jak czyścić brudne łapy po spacerze

- Jak zapobiegać przegrzaniu się podczas długich spacerów

- Jak przygotować psa do podróży samolotem

- Najlepsze gryzaki dentystyczne do utrzymania czystości zębów psa

- Jak wprowadzić psa do nowego harmonogramu karmienia

- Moc symulacji: Bliźniaki cyfrowe w planowaniu logistycznym

- Automatyzacja zbierania danych w łańcuchu dostaw

- Widoczność łańcucha dostaw w celu optymalizacji zarządzania transportem

- Bliźniak cyfrowy dla zrównoważonego zarządzania i praktyk łańcucha dostaw