Torre de Control de la Cadena de Suministro: Centralizando Operaciones con Tecnología

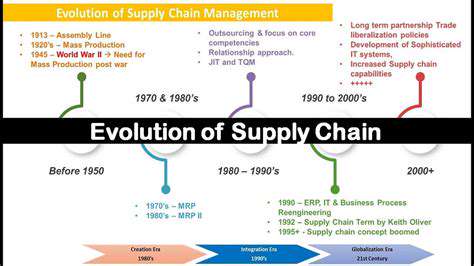

La Evolución de la Gestión de la Cadena de Suministro

Los Primeros Días de la Gestión de la Cadena de Suministro

Las cadenas de suministro tempranas eran en gran medida reactivas

Análisis Predictivo y Toma de Decisiones Proactivas

Entendiendo el Poder del Análisis Predictivo

El análisis predictivo, un componente crucial de una robusta torre de control de la cadena de suministro, aprovecha los datos históricos y los algoritmos estadísticos para predecir...

Optimizando Procesos para la Eficiencia

Optimizando el Flujo de Información

Centralizar los datos de varios puntos de la cadena de suministro, como niveles de inventario, estado de los pedidos y detalles de transporte, es crucial para optimizar los procesos. Esta vista consolidada

THE END

More about Torre de Control de la Cadena de Suministro: Centralizando Operaciones con Tecnología

- Estrategias efectivas para frenar el hábito de los perros de excavar

- Ayudando a tu perro a sentirse cómodo durante el embarazo

- ¿Cómo prevenir la rivalidad entre hermanos perros?

- Repelentes naturales de pulgas para perros

- Cómo hacer la transición de su perro a un nuevo ambiente hogareño

- ¿Cómo reconocer los síntomas de la dirofilariosis canina?

- ¿Cómo identificar los efectos secundarios de la vacuna en los perros?

- ¿Cómo desenredar el pelo enmarañado de tu perro sin lastimarlo?

- Cómo prevenir la formación de nudos en el pelaje de tu perro

- Los mejores juguetes para masticar para promover la salud oral en perros

- ¿Cómo proteger los dientes de su perro a medida que envejece?

- IA para la Detección de Anomalías en la Ciberseguridad de la Cadena de Suministro