車両艦隊の予測保全のためのデジタルツイン

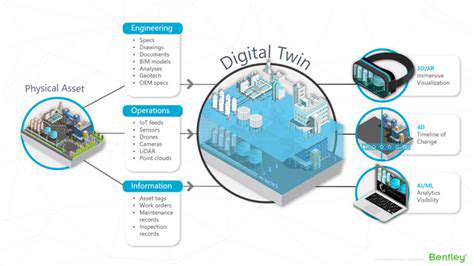

Data Acquisition and Integration

A crucial first step in building a digital twin is acquiring accurate and comprehensive data from the physical system. This includes sensor readings, operational logs, and historical records. Effective data collection is fundamental to the digital twin's fidelity and reliability. Integrating these diverse data sources into a cohesive format ensures accessibility and usability by the digital twin's components.

Model Development and Parameterization

Once data is acquired and integrated, the next stage involves developing a robust digital model. This model acts as a virtual representation of the physical system, capturing its structure, behavior, and interactions. Rigorous parameterization using the acquired data ensures the model's accuracy and representativeness of the real-world system. This process is iterative and often requires adjustments based on ongoing analysis.

Data Validation and Verification

Establishing the accuracy and reliability of the digital model is paramount. This involves rigorous validation and verification processes, comparing the model's predictions with the actual behavior of the physical system. Identifying discrepancies between the model and the real-world system is key to refining the model and improving its predictive capabilities. This iterative process ensures the digital twin remains a reliable representation over time.

Real-time Simulation and Analysis

The true power of a digital twin lies in its ability to simulate real-time scenarios and provide insights. Sophisticated algorithms simulate different operational conditions and predict potential outcomes. This facilitates issue analysis, process optimization, and proactive management of the physical system. Insights from simulations enable data-driven decisions and enhance operational efficiency.

Integration with Existing Systems

The digital twin should seamlessly integrate with existing systems and workflows. This ensures the insights generated can be effectively utilized and acted upon by stakeholders. Integration often involves APIs and data exchange protocols, enabling real-time data flow between the digital twin and other systems.

Visualization and User Interface

A well-designed user interface is crucial for effective interaction with the digital twin. Intuitive visualizations of data and simulation results are essential for users to understand the model's outputs and make informed decisions. Clear and concise visualizations help stakeholders grasp complex information and gain valuable insights. Customizable dashboards and interactive tools cater to specific user needs.

Security and Privacy Considerations

As digital twins handle sensitive data, robust security measures are essential. Data encryption, access controls, and regular security audits protect the integrity and confidentiality of information. Compliance with privacy regulations ensures the digital twin adheres to legal and ethical data handling requirements.

Predictive Maintenance Algorithms and Anomaly Detection

Predictive Maintenance: A Foundation

Predictive maintenance (PdM) is crucial in modern industrial operations, aiming to anticipate equipment failures before they occur. This proactive approach reduces downtime and associated costs by enabling timely maintenance interventions. By leveraging data analytics and sophisticated algorithms, PdM systems analyze equipment performance data to identify subtle patterns and anomalies indicating potential failures.

A fundamental aspect of PdM is its ability to extract valuable insights from vast operational data. These insights provide a clearer picture of equipment health and predict potential issues, minimizing costly breakdowns and maximizing efficiency.

Machine Learning Algorithms

Machine learning (ML) algorithms play a pivotal role in predictive maintenance. These algorithms are trained on historical data to identify patterns and anomalies related to equipment performance. Models like support vector machines (SVMs), artificial neural networks (ANNs), and decision trees are employed based on equipment characteristics and data nature.

By analyzing historical data, these algorithms establish a baseline of normal operation for each piece of equipment. Deviations from this baseline are flagged as potential issues, enabling proactive maintenance and reducing unplanned downtime.

Statistical Process Control (SPC) Methods

Statistical Process Control (SPC) methods provide a structured framework for analyzing data and identifying equipment issues. SPC techniques focus on deviations from established control limits, signaling potential failures.

SPC methods effectively identify patterns of wear and tear, vibration levels, and other critical parameters indicating impending failures. Their application develops predictive models based on statistical analysis of historical data, offering valuable insight into equipment health.

Time Series Analysis

Time series analysis identifies trends and patterns in time-dependent data. This data, including parameters like vibration, temperature, and pressure, predicts future equipment performance and identifies potential failures.

Analyzing temporal relationships between these parameters identifies subtle changes indicating impending failures. This capability enables proactive maintenance, minimizing downtime and associated costs.

Sensor Data Integration

Effective predictive maintenance relies on integrating data from various sensors monitoring equipment performance. These sensors provide real-time data on critical parameters, including temperature, vibration, pressure, and current, crucial for identifying anomalies and predicting failures.

Sophisticated data analysis tools process and interpret vast amounts of sensor data. Aggregating and analyzing this data develops predictive models to anticipate equipment failures and enable timely maintenance actions.

Fault Detection and Diagnosis

An essential aspect of PdM is detecting and diagnosing equipment faults. Fault detection algorithms identify anomalies in sensor data, enabling the identification of potential equipment problems.

Accurate fault diagnosis determines the specific cause of the fault and identifies necessary maintenance actions. This ability allows for targeted repairs and maintenance, minimizing downtime and maximizing equipment lifespan.

Data Visualization and Interpretation

Data visualization plays a critical role in predictive maintenance, enabling effective interpretation of complex data sets. Visual representations of equipment performance data, such as charts and graphs, help identify patterns and anomalies indicating potential failures.

Effective visualization techniques enable engineers and maintenance personnel to quickly understand and interpret data, leading to improved decision-making and proactive maintenance strategies. This ultimately contributes to reduced downtime and increased operational efficiency.

Real-World Applications and Benefits

Predictive Maintenance in Manufacturing

Digital twins offer significant advantages in predictive maintenance for manufacturing processes. By creating a virtual representation of physical assets, engineers can simulate various operating conditions and stress scenarios without impacting real-world equipment. This allows for identifying potential failures before they occur, enabling proactive maintenance schedules and minimizing costly downtime. Predictive maintenance using digital twins is crucial in high-value manufacturing environments where unexpected equipment failures lead to significant financial losses.

The ability to analyze historical operational data and real-time sensor data within the digital twin enables identifying patterns and anomalies indicative of impending failures. This allows maintenance teams to schedule interventions before breakdowns occur, ensuring optimal equipment performance and reducing catastrophic failure risks. This proactive approach is more efficient and cost-effective than reactive maintenance strategies.

Improving Equipment Reliability

Digital twins play a critical role in improving equipment reliability by providing a detailed understanding of its performance characteristics. A digital twin incorporates data from various sources, including sensors, maintenance records, and historical operating data, to create a comprehensive model of the equipment's behavior over time. This detailed model enables engineers to identify potential weaknesses and vulnerabilities within the system, leading to targeted solutions to enhance reliability.

Through simulations and analysis within the digital twin, engineers can optimize maintenance strategies, improve component design, and proactively address potential issues. This proactive approach dramatically improves equipment reliability, reducing downtime and increasing operational efficiency.

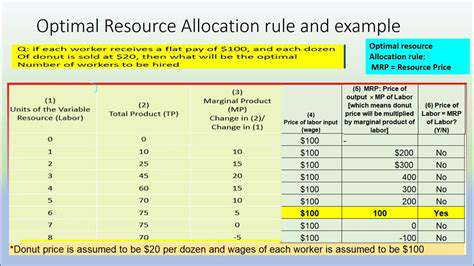

Optimizing Maintenance Strategies

Digital twins enable optimization of maintenance strategies by simulating different maintenance scenarios. This allows engineers to evaluate the impact of various maintenance schedules, repair procedures, and spare part requirements on overall equipment performance. Simulating these scenarios in a virtual environment reduces the risk associated with implementing new maintenance strategies in the real world.

By analyzing simulation results, maintenance teams identify the most effective maintenance strategies, minimizing downtime and maximizing equipment lifespan. This optimization process achieves cost savings and ensures consistent high performance in the long term.

Enhanced Safety and Risk Management

Digital twins contribute to enhanced safety and risk management by identifying potential hazards and vulnerabilities within the system. Simulating various operating conditions and scenarios allows engineers to identify potential safety risks and implement preventive measures to mitigate them. This proactive approach reduces the likelihood of accidents and incidents.

Real-time data visualization and analysis within the digital twin environment provide critical tools for identifying and mitigating risks, ensuring personnel safety and minimizing potential damage to equipment and the environment.

Remote Monitoring and Control

Digital twins enable remote monitoring and control of equipment, offering significant advantages in geographically dispersed operations. Engineers can monitor equipment performance remotely, access real-time data, and adjust operating parameters without being physically present at the site. This capability is especially valuable for managing equipment in remote or hazardous locations.

Remote monitoring and control through the digital twin reduce response time to issues and allow proactive intervention. This reduces downtime, enhances operational efficiency, and ensures smooth and continuous operation of critical equipment regardless of location.

Data-Driven Decision Making

Digital twins facilitate data-driven decision making by providing a centralized platform for collecting, analyzing, and visualizing data from various sources. This comprehensive data analysis allows engineers to make informed decisions regarding equipment maintenance, operation, and optimization. Insights gained from this analysis improve operational efficiency, reduce costs, and enhance safety.

Leveraging data accumulated and analyzed within the digital twin enables decision-makers to gain a deeper understanding of the system's behavior and make data-informed decisions leading to improved performance and reduced risk in the long term.