Construindo uma plataforma de otimização de cadeia de suprimentos baseada em IA

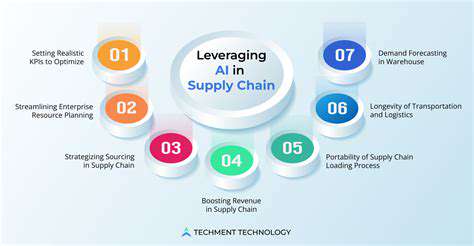

Definindo a Necessidade de IA em Cadeias de Suprimentos

Definindo o Âmbito dos Desafios da Cadeia de Suprimentos

A cadeia de suprimentos moderna enfrenta um complexo problema

Construindo uma Cadeia de Suprimentos à Prova de Futuro com IA

Otimizando para Resiliência

Uma cadeia de suprimentos à prova de futuro exige uma estrutura robusta e adaptável. Isso envolve proativamente

THE END

More about Construindo uma plataforma de otimização de cadeia de suprimentos baseada em IA

- Cuidados com cães com artrite

- Produtos calmantes para ajudar cães ansiosos a relaxar

- Como identificar os sinais de gravidez em seu cão

- Como ajudar seu cão a aprender novos truques mais rápido

- Como ensinar seu cão a usar sapatos ou botas

- As melhores gaiolas de viagem para cães para todos os orçamentos

- Como proteger seu cão de pragas da primavera

- Dicas de emergência para um cão que engoliu um objeto estranho

- Superando os Desafios de Dados na Implementação de Gêmeos Digitais

- Construindo uma Cadeia de Suprimentos Resiliente por meio da Integração de Tecnologia

- A Proposta de Valor das Plataformas de Cadeia de Abastecimento Unificadas

- Simulando o Impacto de Desastres Naturais com Gêmeos Digitais