The Business Case for Robotics in Manufacturing Supply Chains

Improving Supply Chain Resilience and Adaptability with Robotics

Optimizing Inventory Management

Robotics are revolutionizing inventory management by automating tasks like tracking, sorting, and picking. This automation leads to significant improvements in efficiency, reducing the time needed for these processes and minimizing human error. By precisely tracking inventory levels in real-time, robotic systems offer a more accurate picture of stock availability, enabling businesses to anticipate demand fluctuations and adjust production accordingly. This proactive approach minimizes costly stockouts and overstocking, ultimately boosting profitability.

Furthermore, the ability to accurately predict and respond to demand fluctuations through real-time inventory tracking is a critical component of supply chain resilience. This proactive approach empowers businesses to adjust production schedules and allocate resources more effectively, ensuring that products are available when and where they are needed, even during periods of high demand or unexpected disruptions.

Enhanced Order Fulfillment Speed

Implementing robotic systems in order fulfillment processes drastically accelerates order processing times. Robots can handle large volumes of orders with unparalleled speed and precision, significantly reducing the time it takes to fulfill customer requests. This enhanced speed translates directly into improved customer satisfaction and a competitive advantage in the market.

By automating tasks like picking, packing, and shipping, robots minimize manual handling and the potential for errors, leading to a more streamlined and efficient order fulfillment process. This increased speed and accuracy in order processing is crucial for maintaining customer satisfaction and building a strong brand reputation.

Improved Warehouse Safety and Ergonomics

Robotic automation can significantly reduce the risk of workplace injuries commonly associated with manual material handling in warehouses. By taking over physically demanding tasks, robots minimize the strain on human workers, leading to a safer and healthier work environment. This positive impact on employee safety not only reduces workers' compensation costs but also boosts morale and productivity.

Predictive Maintenance and Proactive Repair

Robotic systems equipped with advanced sensors can monitor equipment performance in real-time, detecting subtle signs of potential malfunction before they escalate into costly breakdowns. This proactive approach to maintenance allows businesses to schedule repairs preemptively, minimizing downtime and ensuring continuous operations. The enhanced ability to predict and prevent equipment failures is critical for maintaining a robust and adaptable supply chain, enabling businesses to respond quickly to unexpected disruptions.

Adaptability to Changing Demand and Supply

The ability of robotic systems to adapt to fluctuating demand and supply is a key advantage in today's dynamic business environment. Robotic systems can be reprogrammed and reconfigured quickly to handle changes in production schedules and order volumes. This adaptability ensures that businesses can respond effectively to unexpected market shifts and maintain a resilient supply chain, even during periods of high demand or unexpected disruptions.

Robotics can also help businesses adapt to changes in the supply chain, such as material shortages or transportation disruptions. By automating processes and optimizing workflows, robotic systems help businesses overcome these challenges and maintain their operational efficiency and resilience.

Reduced Labor Costs and Increased Productivity

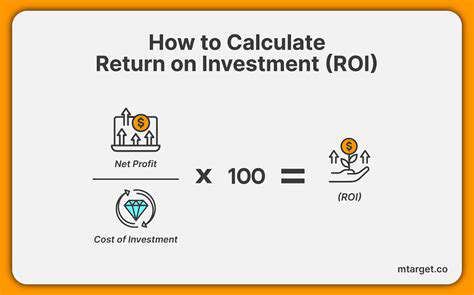

While initial investment in robotic systems can be significant, the long-term cost savings and increased productivity often outweigh the initial expense. By automating repetitive and labor-intensive tasks, robots free up human workers to focus on higher-value activities, leading to increased overall productivity. This enhanced productivity, combined with a reduction in labor costs through automation, creates a significant return on investment for businesses that adopt robotic solutions in their supply chains.

The ability to scale operations efficiently and effectively with robotic systems is particularly valuable in rapidly growing businesses. Robots can handle increased workloads without the need for significant increases in human labor, enabling businesses to maintain operational efficiency and adapt to evolving market demands.

- How to safely cut your dog’s nails at home

- What to do if your dog shows symptoms of anxiety

- Why regular grooming is essential for your dog’s health

- The best chew toys for anxious dogs

- What to feed a dog recovering from illness

- How to stop your dog from chewing through leashes

- Common health issues in senior dogs and prevention tips

- The Impact of Robotics on Supply Chain Labor Force

- Digital Twin Technology for Supply Chain Resilience Planning

- Robotics for automated cross docking operations

- Data Visualization Dashboards for Supply Chain Performance

- AI for Automated Order Fulfillment: Boosting Speed and Accuracy