供应链资产的预测性维护:数据驱动方法

Effective predictive maintenance hinges on the ability to collect and analyze relevant data. This involves meticulously monitoring various factors, including sensor readings, machine performance metrics, and environmental conditions. Sophisticated data collection methods, such as IoT sensors and advanced monitoring systems, capture detailed insights into equipment behavior.

The collected data is then processed and analyzed using advanced analytics techniques to identify patterns, anomalies, and potential failure points. Machine learning algorithms play a critical role in this process, enabling the system to learn from historical data and predict future performance trends. This data-driven approach is essential for accurately anticipating maintenance needs.

Implementing Predictive Maintenance Strategies

Successful implementation of predictive maintenance strategies requires a multi-faceted approach. This includes establishing clear KPIs (Key Performance Indicators) to measure the effectiveness of the system and regularly evaluating the performance of equipment. Defining specific maintenance schedules based on predicted failure points is also crucial. This involves utilizing real-time data analysis to adjust schedules as needed, ensuring optimal equipment performance and minimizing downtime.

Furthermore, comprehensive training and development programs for maintenance personnel are essential for effectively using the predictive maintenance system. This will ensure that they understand how to interpret the data and utilize the insights to proactively address potential issues.

Integrating Predictive Maintenance with Supply Chain Planning

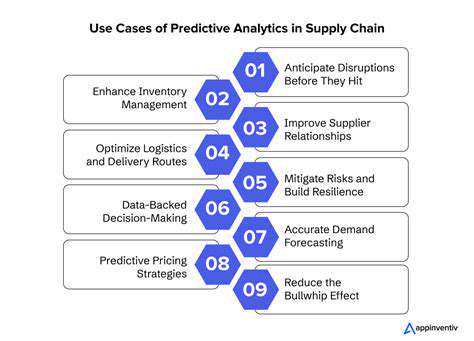

Predictive maintenance isn't just about individual equipment; it's about integrating insights into the broader supply chain planning process. By incorporating predicted maintenance schedules into inventory management systems, companies can anticipate potential disruptions and adjust inventory levels accordingly. This proactive approach minimizes the risk of stockouts and ensures uninterrupted supply chain flow.

Integrating predictive maintenance into demand forecasting models enables companies to anticipate potential issues and adjust production schedules. This proactive approach enhances the responsiveness of the supply chain and minimizes the impact of unexpected equipment failures.

Optimizing Maintenance Costs and Resource Allocation

Predictive maintenance offers significant cost savings by reducing reactive maintenance expenses and minimizing costly downtime. By scheduling maintenance proactively, companies can optimize resource allocation, ensuring that maintenance teams are deployed effectively and efficiently to address predicted failures. This proactive approach minimizes unnecessary costs and maximizes the return on investment.

Furthermore, the ability to predict potential equipment failures allows for better resource planning and allocation. Companies can allocate personnel and spare parts more effectively, minimizing the risk of delays and optimizing overall operational efficiency.

Ensuring Data Security and Privacy in Predictive Maintenance Systems

Implementing predictive maintenance systems necessitates robust data security and privacy measures. The large volume of sensitive data collected from equipment sensors must be protected from unauthorized access and breaches. This includes implementing encryption protocols, access controls, and regular security audits to protect the integrity of the data.

Furthermore, adherence to data privacy regulations is crucial. Companies must ensure that the collected data is used ethically and responsibly, complying with all relevant regulations to protect the privacy of individuals and maintain trust. This careful consideration of data security and privacy is crucial for long-term success in implementing predictive maintenance.

The Benefits of Predictive Maintenance for Supply Chain Optimization

Predictive Maintenance: A Proactive Approach

Predictive maintenance is a proactive approach to maintenance, focusing on preventing equipment failures before they occur. By analyzing data from various sources, such as sensors and historical records, predictive maintenance systems can identify potential issues and predict when maintenance is needed. This approach allows for optimized maintenance schedules, reducing downtime and increasing equipment lifespan.

This shift from reactive to proactive maintenance translates to significant cost savings. By addressing issues before they escalate, companies can avoid costly repairs and replacements, as well as the potential loss of production. Predictive maintenance also contributes to improved safety by identifying potential hazards earlier in the process.

Reduced Downtime and Increased Productivity

One of the most significant benefits of predictive maintenance is the reduction in unplanned downtime. By anticipating potential failures, maintenance teams can schedule preventative work during periods of lower production or demand. This proactive approach minimizes the impact of unexpected equipment failures on overall productivity and output.

Predictive maintenance leads to a more stable and predictable production process. Knowing when maintenance is needed allows for more accurate scheduling and resource allocation, leading to smoother operations and improved efficiency.

Enhanced Equipment Lifespan

By identifying and addressing potential issues early, predictive maintenance extends the lifespan of equipment. Regular preventative maintenance, guided by predictive insights, helps to maintain optimal equipment condition, reducing the likelihood of premature wear and tear, and extending the useful life of assets.

This prolongs the return on investment in the equipment, as it avoids costly replacements and repairs that would otherwise be required if issues were left unaddressed.

Improved Safety and Operational Efficiency

Predictive maintenance plays a critical role in improving safety within a facility. By identifying potential hazards and equipment weaknesses before they become dangerous, organizations can implement corrective actions to mitigate risks and ensure a safer working environment for employees.

Predictive maintenance also streamlines operations and enhances overall efficiency. With accurate predictions, maintenance teams can prioritize tasks, optimize resource allocation, and minimize disruptions to the workflow. This leads to reduced operating costs and improved profitability.

Data-Driven Decision Making

Predictive maintenance is fundamentally data-driven. By collecting and analyzing data from various sources, such as sensor readings, operational logs, and historical maintenance records, companies gain valuable insights into equipment performance and potential failure points.

This data-driven approach enables more informed decisions about maintenance scheduling, resource allocation, and equipment upgrades.

Cost Savings and Return on Investment

Predictive maintenance offers substantial cost savings by reducing unplanned downtime, extending equipment lifespan, and minimizing the need for costly emergency repairs. These cost savings significantly improve the return on investment (ROI) in the long run. Ultimately, predictive maintenance translates to increased profitability and operational efficiency.

By avoiding unexpected breakdowns and costly repairs, companies can achieve substantial savings and optimize their overall maintenance budget.